100th YEARS OF GROB’s MARVEL OF HIGH-END MILLING AND LATHE MACHINES FROM GERMANY …GROB G350 ACCESS MODEL IS INTRODUCED

Following a long history of success and approaching its 100th anniversary in 2026, GROB-WERKE is a pioneer in creating innovative and high-quality machine tools in Germany, and to maintain its leadership in the industry, GROB-WERKE is committed to carrying on the development continuously. For almost a century, GROB-WERKE has stood for quality, reliability, and innovation. Our success story is a result of our unwavering dedication to development, allowing GROB-WERKE to continue leading the way in creating modern machines and systems for renowned customers worldwide.

To appropriately address future challenges, even in this era of change and globalization, we shall still continue to adhere to our core values and principles in our daily work and suggest that you should experience GROB’s innovative strength by yourself and discover the highlights of GROB’s technical development all along with us.

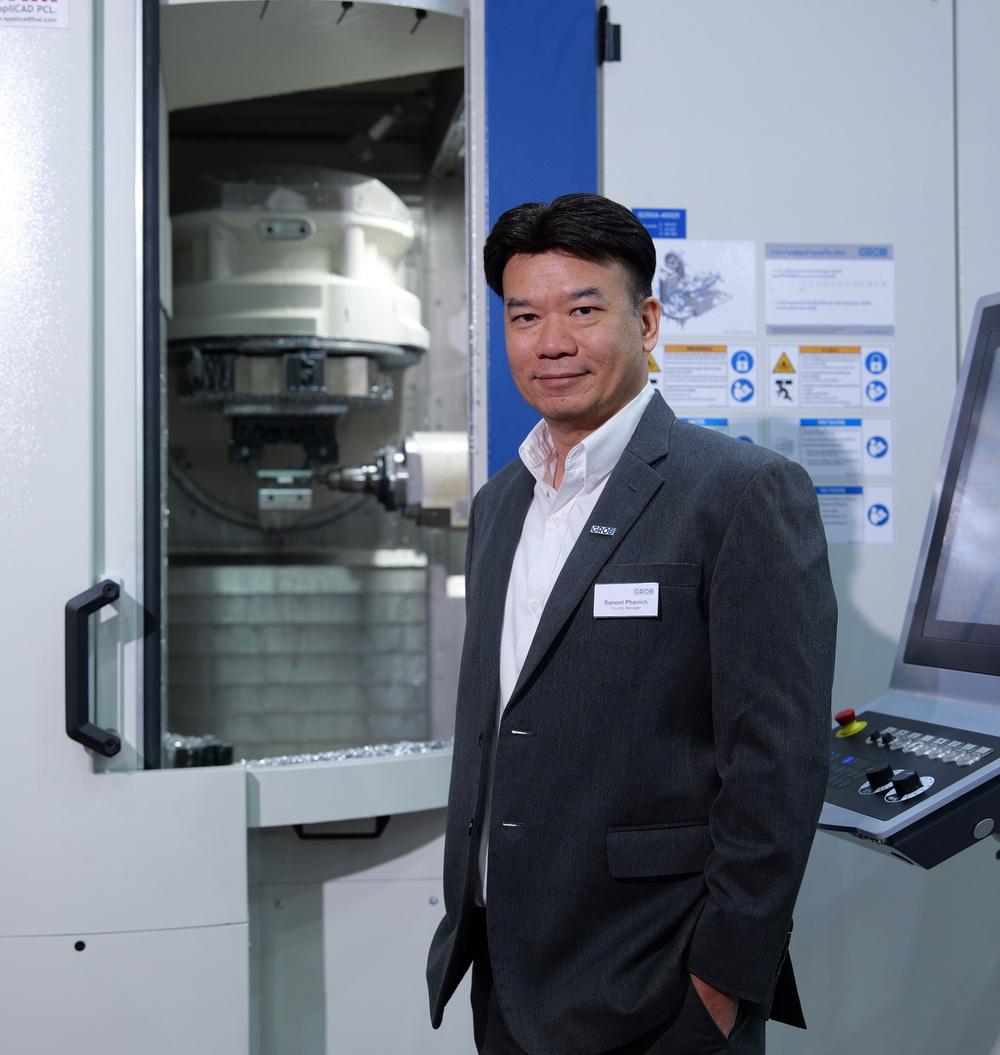

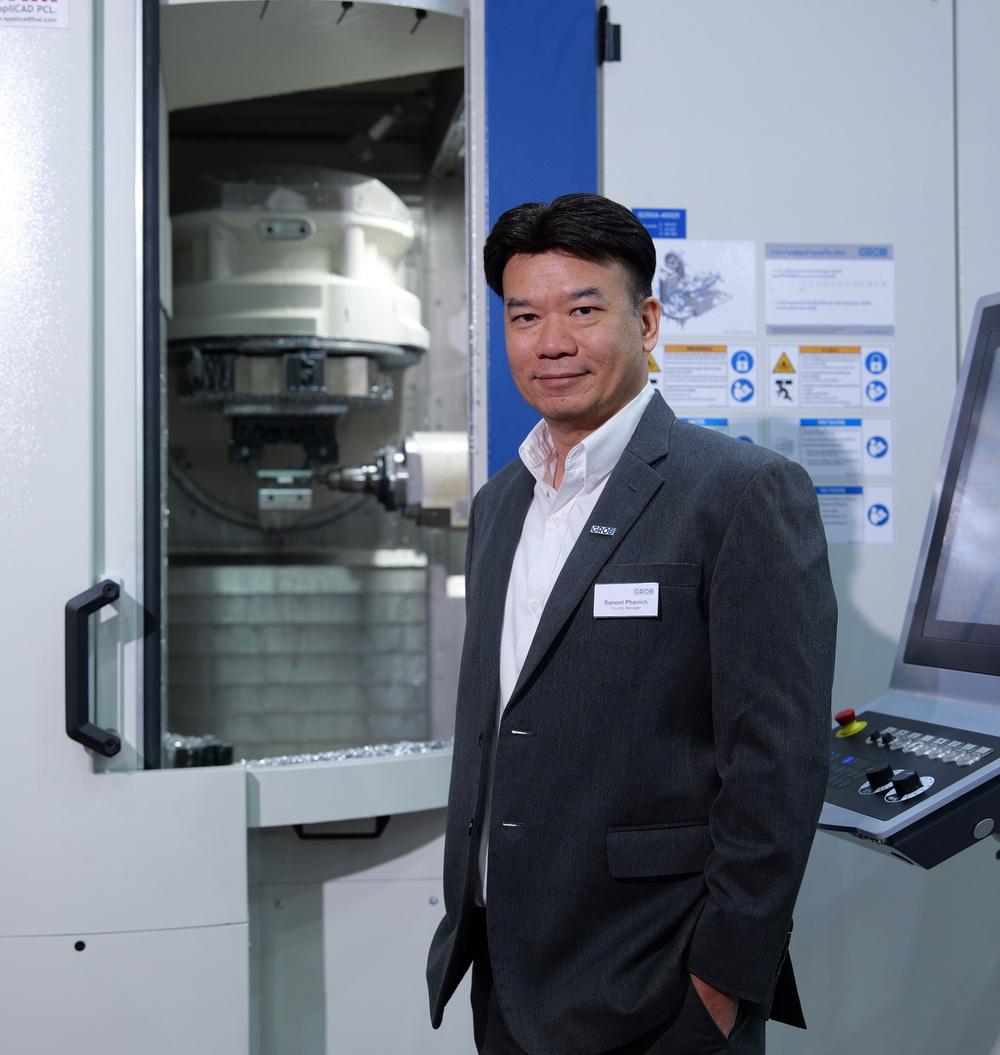

“Manufacturing Review” Magazine had an opportunity to speak with Mr. Sanont Phanich, Country Manager, GROB Machine Tools (Thailand) Co., Ltd., who stated that, GROB is a German company, having 6 factories throughout the world, located in Germany, the USA, Italy, Brazil, India, and China, as well as 16 sales offices globally. In 2026, GROB will celebrate its 100th anniversary. GROB is the manufacturer of machinery and automation systems for manufacturing industry, which is its main business, that has continuously been developed with new machine models being regularly released to the markets. Most recently, the newly launched Universal Machine Centers (UM), a 5-axis CNC milling machine, has received positive user feedback. Its outstanding feature, which distinguishes it from other 5-axis CNC machines, is the table’s ability to work with tooling heads of any angle, and the horizontal spindle, allowing for milling in all directions and angles. The work can be completed with a single setup, significantly reducing working time. In addition, GROB machines have many other outstanding features, but the main ones are as mentioned above. With almost 100 years of experience, GROB incorporates know-how, innovation, and cutting-edge technology into the new machines it offers to the market.

GROB are machines that can serve the purpose of the production needs of all industrial sectors, whether it is the aerospace, mold making, automotive part manufacturing, electronics manufacturing, and medical equipment manufacturing industry or in the energy industry, such as the production of propellers, etc. GROB machines can also incorporate automation systems into their operation, both hardware and software. For example: the Pallet System that can accommodate 15-30 pallets, can be connected to the GROB machine’s operating system for continuous operation and can be programmed to select which pallets to work with. GROB machines have a variety of functions, so, it’s important that the customer’s primary needs are required to take into consideration to ensure the optimal use.

Mr. Phanich further revealed that GROB machines had been in the Thai market for many years. by Mr. Uwe Wedler, Managing Director GROB Asia Pacific Therefore, there are questions as to whether there are the after-sales service in Thailand or not since they are German-made machines. Of course, we do, we have a GROB Machine Tool (Thailand) team to provide the after-sales service to customers in Thailand. We are confident in the technology and quality of GROB machines because their quality and standards are guaranteed by customers worldwide, especially in Thailand where large factories have already use GROB machines in their parent companies abroad which makes it easy for them to invest in GROB machines because they are already using them and have seen the quality and standards of the machines. Therefore, GROB Machine Tool (Thailand) needs a service team to meet the needs of customers in Thailand. GROB Machine Tool (Thailand) has been established in Thailand for 4 years and has approximately 50 GROB machines in the manufacturing industry.

At Metalex 2025, GROB placed in the exhibition the GROB G350 access model. The advantage of this machine is its economical price while being packed with German technology quality, including features, overhead machining, and horizontal spindle. It offers a more affordable price, addressing the needs of today’s businesses with limited budgets but a desire to improve the production quality. GROB is confident that the machines can significantly increase customers’ efficiency in terms of faster production, reduce setup time, lower maintenance costs, and save energy. Although each machine may cost more but, it will provide a quicker break-even point on investment.

“The unique feature of GROB machines is the horizontal spindle and table that can perform overhead machining. The standard size has an A-axis that can rotate 230 degrees, allowing for workpiece clamping and completion in a single pass. Chips are ejected via a conveyor, keeping the machine room clean at all times. In addition, the spindle can betool-changed in the tunnel, saving time compared to typical 5-axis machines, and this model can change up to 60 tooling.”

The GROB team in Thailand has extensive knowledge and expertise because the team members had been trained by the parent company to meet the needs of customer services in Thailand. We can provide 24 Hrs services, including Line chats, to answer customers’ questions immediately. Furthermore, we stock spare parts for every component of GROB machinery, so customers can rest their trust in us in terms of our machinery products.