DNE LASER Penetrates Metal Cutting Machine Market in Thailand to Respond to High-efficiency Production, Help Reduce Costs and Creating Profits.

“DNE LASER” is a leading global fiber laser manufacturer brand from China with a commitment to providing advanced products to customers worldwide and developing high-efficiency and innovative products which will help increase productivity in the manufacturing industry.

With high-quality products and excellent after-sales service, DNE LASER’s products and services reach almost a hundred countries and regions worldwide, and are widely used in electric power, automotive manufacturing, mechanical equipment, electrical equipment, sheet metal manufacturing, aerospace, shipbuilding, oil pipelines, new energy, and many more.

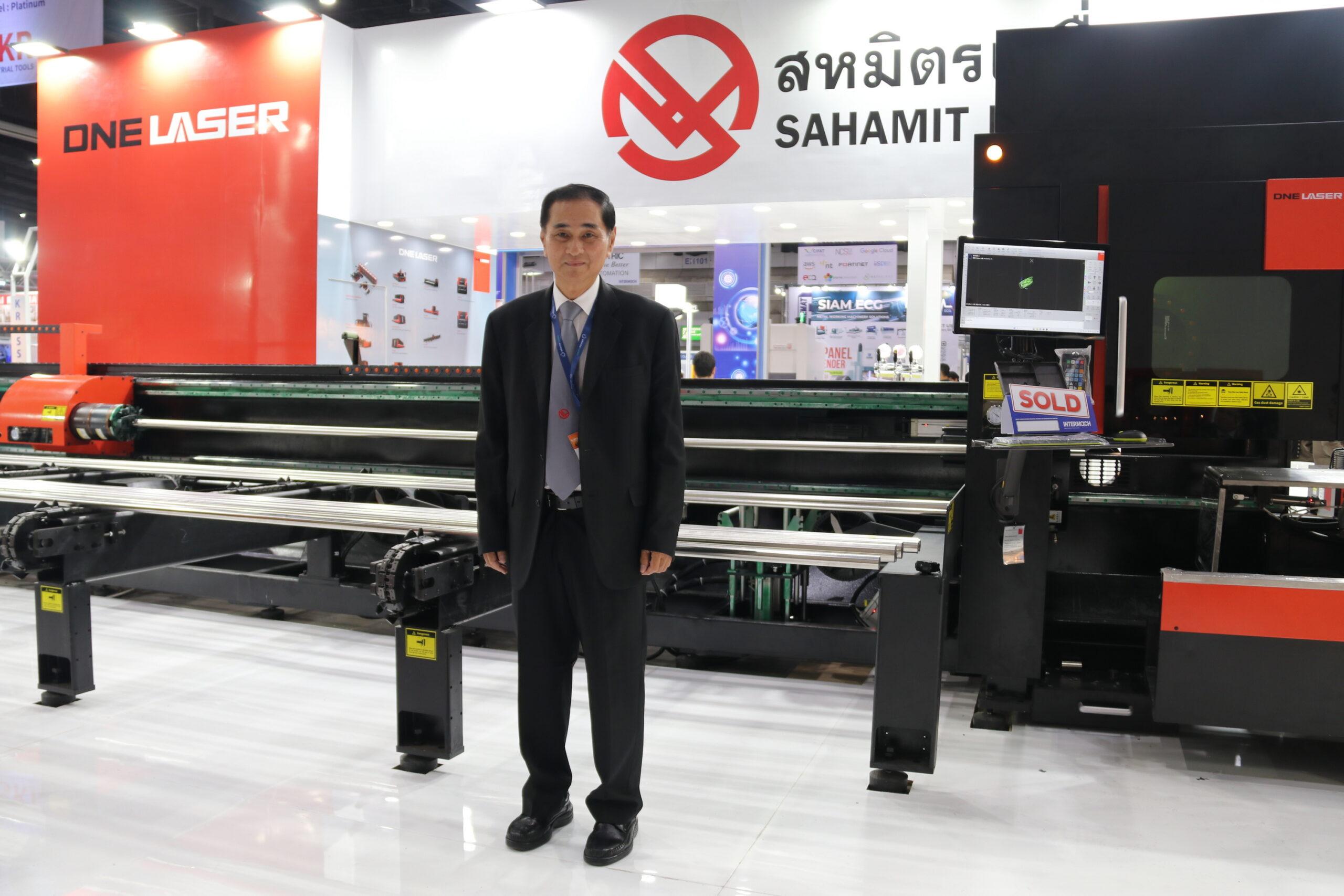

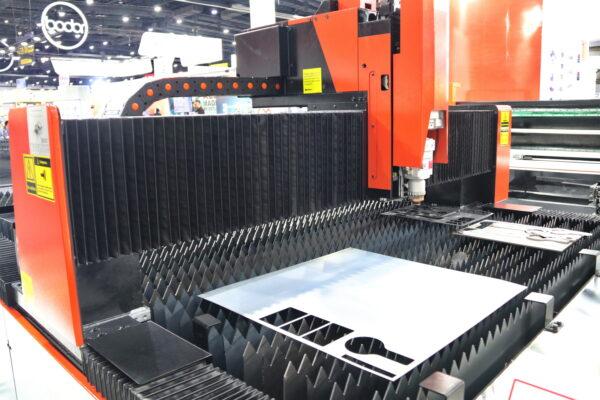

Mr. Phut Sorayarnthanawut, Managing Director, Sahamit Machinery Public Company Limited, revealed that at the Intermach 2025, the company brought in the metal cutting machines for presentation to the event visitors. The cutting machines on display were the fiber lasers of “DNE LASER” brand of 3,000-watt capacity used for cutting sheet metal and pipe workpieces of the size ranging from 1 mm. to 20 mm. Because the machines were not too expensive and could cut sheet metal, aluminum, and stainless steel, etc., therefore, they would ideally be suitable for SME entrepreneurs with a small investment budget. In addition, DNE LASER had machines of the sizes for customers to choose to appropriately suit their production processes.

“DNE LASER is emerged from developed technology in terms of the intelligence in the automatic system for metal cutting works. Because such technology has been developed for high efficiency in terms of both the accuracy and cutting speed and transferred from Bystronic fiber laser machine manufacturer, it must be admitted that the current cutting industry has developed very quickly. Over in the past, the machine could cut only in straight lines, but nowadays, the cutting technology can cut workpieces in every angle.”

In terms of the after-sales service for DNE LASER brand fiber laser machines, Sahamit Machinery Public Co., Ltd., as a distributor in Thailand, has a team of experts with experience of more than 7 years readily available to provide maintenance services for the machines and spare parts around the clock. Because over in the past, the company was one of the first to import fiber laser machines from China fore sales in Thailand, so, meanwhile, the company has accounted for more than 100 machines in the manufacturing industry. Therefore, customers can be reassured that when they use our machines in their productions, they will receive consistent care from the company.

Business Tips…Experts

Mr. Sorayarnthanawut makes a recapitulation on the trend of the machinery market in Thailand’s industry that the current Thai industry is gradually getting smaller and smaller, not growing much, unlike in the 90s era or in 2000, when the growth rate was very high with a great number of many small, medium and large factories emerged. Business entrepreneurs were profitable and happy with their work, which led to the growth of domestic industries. Many foreign investors came to invest consequently resulting in the overall economy to be expanded. But, at the present, the economy has declined significantly due to the slowdown in the global trades, the increase in trade barriers or regulations to the extent of causing a continuous impact on Thai industries. Coupled with the introductions of cheap products into Thailand, Thai entrepreneurs have been greatly and inevitably affected, particularly, the SMEs. The entrepreneurs who can still strive to stand would be multinational companies or medium and large entrepreneurs, thus making the overall economy in the country slow down. For such reason, small entrepreneurs have slowed down their investments in new technologies. If they should invest in the production, the price would be cut. So, it would not be worthwhile investing in new technologies. Therefore, they opt to use the same old existing technology causing the efficiency and the production costs per unit being unable to compete or jobs from medium and large factories having new technologies that always come, being unable to be sub-contracted. In the future, small factories that do not improve or develop their efficiencies will continue to decrease in number, leaving only factories with the capacity to develop production technologies, medium and large factories to remain.