JATCO, a manufacturer of automotive transmissions, aims to develop technology that supports future vehicles.

JATCO (Thailand) Co., Ltd., established with support from the Thai government in 2011, is JATCO’s third overseas manufacturing location following the establishment of production bases in China and Mexico. The company began to operate and start manufacturing processes with an annual manufacturing capacity of 500 thousand units. In addition, JATCO (Thailand) Co., Ltd., is the first CVT manufacturing company in Thailand. The CVT model produced in our factory is not only used in the Nissan March, but also in other car models such as the Nissan Sylphy, Suzuki Swift, Suzuki Ciaz, and Mitsubishi Attrage.Going forward, we intend to change Thailand for the better with our environmentally friendly CVT model.

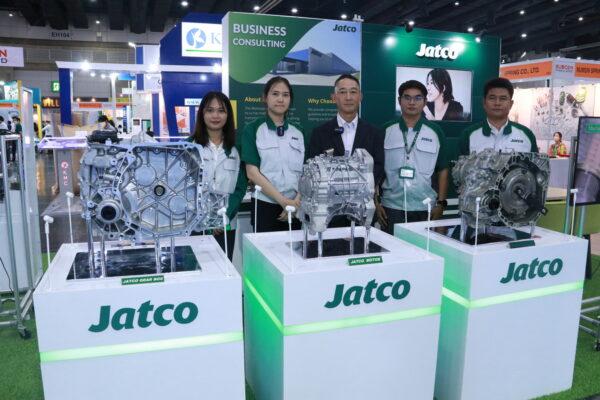

JATCO has been a specialized manufacturer of automatic transmissions for automobiles for more than 50 years, providing a wide range of products to customers around the world, ranging from step ATs to environmentally friendly CVTs (Continuously Variable Transmission) and transmissions for hybrid vehicles.

JATCO (Thailand) Co., Ltd., established as an Asian hub among the production bases, started CVT production in September 2013 and has continued production for more than 10 years. It is an integrated plant for CVT production from casting to machining, heat treatment, and assembly.

Furthermore, in 2021, a new production line for motors and reduction gears for electric vehicles was launched. The automotive industry is currently undergoing a period of great change, including electrification and automated driving, against a backdrop of global environmental improvement. We are committed to solving social issues through various activities including our business here in Thailand.

Developing a Limitless Transmission for Future Vehicles

Our CVT with an auxiliary gearbox is for mini and small FWD vehicles. With its new-structure auxiliary transmission system, this CVT increases the gear ratio range, and friction-reduction technology realizes enhanced fuel efficiency as well as great driving performance, aiming for the significantly improved environmental performance expected from it. Furthermore, the reduction in size and weight expands its applicability to a broader range of vehicles including mini-vehicles and small-sized vehicles.

On the other hand, what is key for stable business continuity is our human resources. In order to tackle various social issues, it is necessary to develop new business areas, and in order to provide new value, it is important for each employee to exercise leadership and work as a team. By valuing these employees and taking on challenges together, we aim to be a company that is loved by the local community.