EMO 2025 is Pushing AI and Automation for Greater Competitiveness In Global Industry

EMO 2025, Siemens Data license agreement at Siemens, Germany, Hall 6, F30, persons from left to right: Prof. Christian Brecher, Chair of Machine Tools RWTH/WZL, Dieter Lindemayer, VP Division Innovation & Technology Voith, William Lee, CEO Renishaw, Achim Beltz, CEO Business Unit Motion Control, Siemens AG, German Wankmilller, CEO Grob, Roland Busch, Chief Executive Officer Siemens, Stefanie Frank Head of technology Siemens, Dr. Ing. Stephan Mayer, CEO Machine Tools Trumpf, Dr. Claus Eppler, CTO Chiron Group, Dr. Thorsten Schmidt, CEO Heller

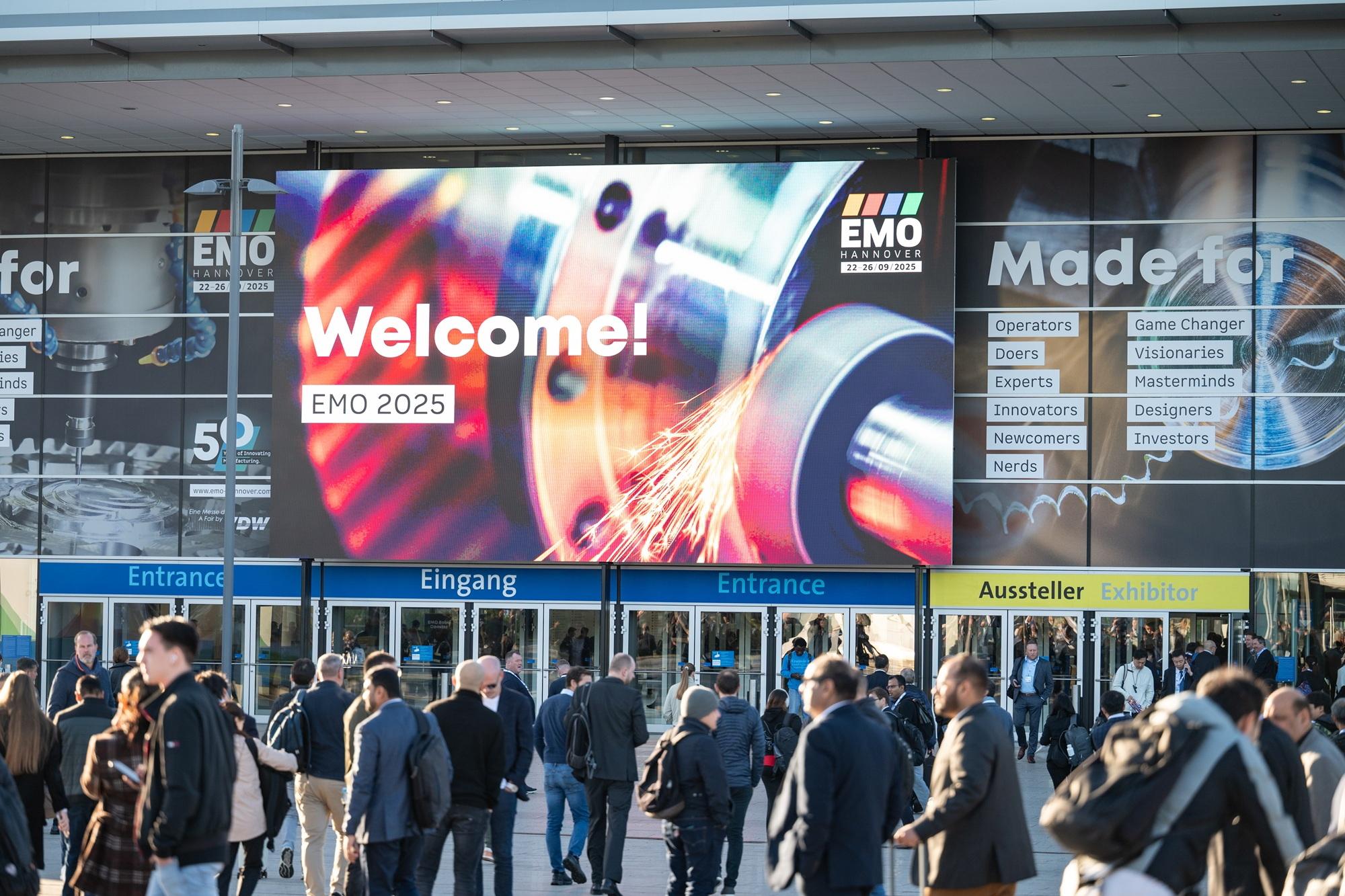

The whole world of metalworking – for five days, Hannover was the venue for EMO, the world’s leading trade fair for production technology. Attracting a number of 80,000 trade visitors from all over the world, the exhibition grounds provided important innovative impulses for greater competitiveness in the industry. The main focus was above all on the topics of automation and artificial intelligence, which have once again found their way into industrial processes as drivers of production efficiency.

Technology, information, exchange, international networking and cooperation this is what EMO has embodied for 50 years. More than 1,600 exhibitors from 45 countries and a diverse supporting program presented a host of solutions for modernizing and upgrading production.

“There is a profusion of smart and impressive technical solutions. This EMO has convincingly demonstrated that,” says Mr. Carl Martin Welcker, General Commissioner of EMO 2025. “For them to be effective, the booster engine of investment now really needs to fire. Many projects are in the pipeline after three years of investment restraint, but the uncertainty in the political sphere continues to put the brakes on investment,” Mr. Welcker continues.

EMO 2025, Gerardi, Italy, Hall 5, C28

EMO 2025, outdoor area, entrance North 1

Automation is a Hot Topic in the Industry

The big topic in the industry is automation. This is driven by costs and a shortage of skilled workers. 50 % of the visitors surveyed are interested in how they can use automation to boost their productivity. “Automation is everywhere here and is going to make a big difference”, says Mr. Aaron Morrill, CNC Mechanic from the USA. The importance of the use of robots is growing, as around 140 robot manufacturers have impressively demonstrated at EMO. Mr. Klaus Winkelmann, CEO of Fanuc Europe, says: “We also see that robots will become increasingly important in the machine tool industry. Industrial robots will coexist with human operators. In the future, they will provide the most efficient solutions.”

Interfaces to Digitalization and Sustainability

More than a third of the trade visitors want to learn about new aspects of digitalization and AI. Automation, digitalization and artificial intelligence ensure higher productivity, efficiency and quality. This also increases sustainability in production, for example by promoting efficiency in energy and materials. Sustainability is an important factor in research and among talented young people.

Top Platform for International Managers

Once again, EMO has proven to be a top platform for managers and buyers. In the visitor survey, more than half of the respondents stated that they were top or middle managers. They also have the authority to make procurement decisions.

Overall, 94% of visitors felt their objectives for the visit had been achieved. 98 percent rated EMO between satisfactory and very good.

“It has proven possible to attract international market leaders in metalworking to EMO and address the new topics in industrial production,” concludes Dr. Markus Heering, Executive Director of the EMO Organizer, the VDW. “As a result, it has consolidated its position as the world’s leading trade fair and barometer of trends,” he summarizes.

EMO 2027 will take place from October 4 to 8 in Milan, Italy.