ISCAR Is About to Change Metal Cutting… Again!

ISCAR has once again revolutionized metal machining with the launch of its major campaign “Logiquick,” combining the words “Logic,” “IQ,” and “Quick.” This emphasizes the core of the campaign, asserting that cutting tools should not only facilitate increased metal removal rates but also exhibit qualities such as repeatability, versatility and user-friendliness

This time, ISCAR has introduced an advanced range of multifaceted cutting tools, including tools for turning, grooving, threading, drilling, and milling. This diverse lineup aims to meet various operational needs effectively.

One of the revolutionized tools is QUICK-X-FLUTE (Figure 1), new family of 90-degree extended flute shell mills with double-sided square inserts. These mills are designed with an optimized flute shape that strikes a balance between tool rigidity and effective chip flow, enabling high Metal Removal Rates (MRR). The developed flute profile enhances vibration resistance, especially during workpiece entry and exit, allowing for increased cutting data and improved productivity. The inner channels of the mill have replaceable nozzles and frontal outlets, facilitating direct High-Pressure Coolant supply (HPC) to the cutting zone. This improves cooling and lubrication, contributing to effective chip control.

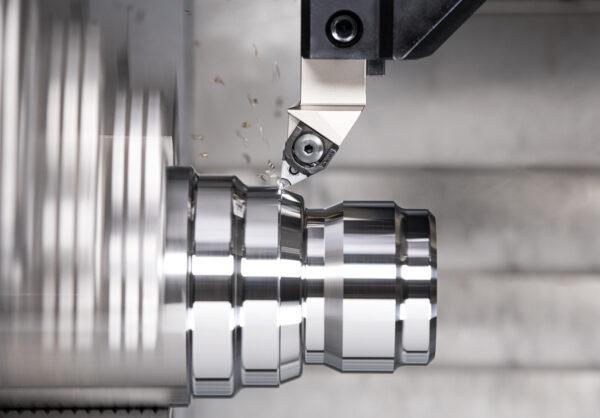

Another interesting product is LOGIQ-6-TURN (Figure.2), a newly designed triangular insert that offers a cost- effective solution for semi-finish and finish turning with a focus on achieving high surface quality. This double-sided insert features a 55° corner angle and positive rake cutting geometry, providing 6 indexable cutting edges. It presents a significant alternative to the standard ISO-type rhombic insert of DCMT type, which only offers 2 cutting edges. One key advantage is the ease with which LOGIQ-6-TURN inserts can be mounted on turning tools designed for triangular TNMG inserts.

These new tools are just a part of the LOGIQUICK campaign. ISCAR also offers a wide range of highly interesting products to meet increased demands, whether it’s for rapid metal removal or advanced machining capabilities.