“Smart Film”, a Workmanship of KMUTT Students, a Self-Light Adjustable and Energy-Generable Film that Can Solve House Heat Sustainably.

KMUTT engineering students have developed a “Smart Film” to be easily installed on house and building window glasses to adjust brightness and generate electricity from sunlight by themselves without any needs to dismantle the structure, to help reduce energy usage in buildings by 22% per year and continuously lead to green technology for the future and Net Zero Energy.

On a day when the world is facing an energy crisis and climate change, the power of the new generation full of creativity is very important in creating innovations for the world, just like the innovations of students of King Mongkut’s University of Technology Thonburi (KMUTT), who have developed the prototype research work, a “Self-Light Adjustable and Energy-Generable Film inside Buildings or “Smart Film” that can adjust the transparency level of the film to suit the brightness of the room and use sunlight to generate electricity to feed the system by itself. It is a new approach that meets the needs of energy use in modern buildings that require both sustainability, beauty, and convenience of use.

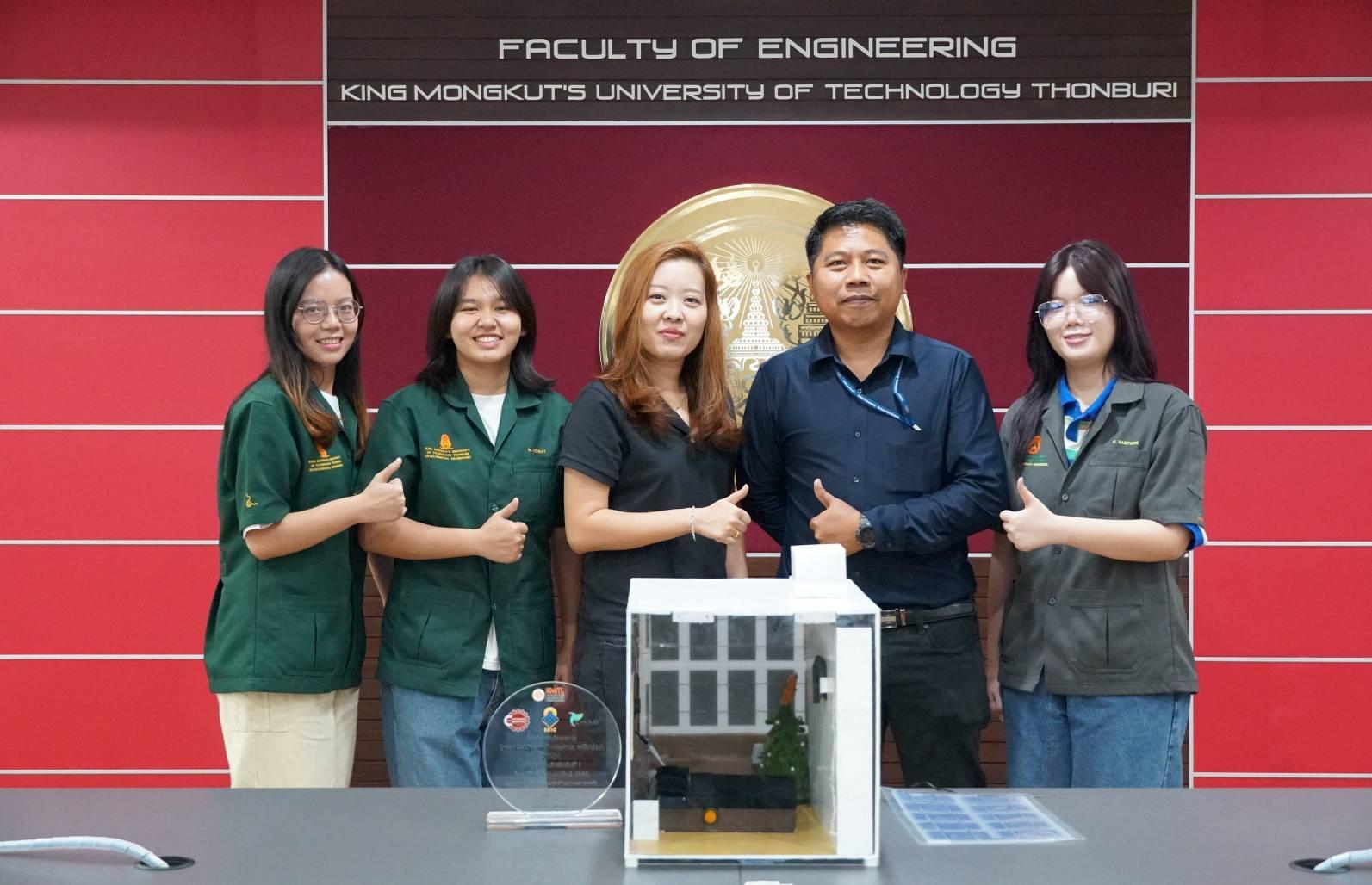

This innovation is invented by the “Power Maker” Team, comprising 3 engineering students, namely: Jirarat Nganrungruang, Patcharaporn Chaikaew from Department of Environmental Engineering, and Sasithorn Pikulkaew from Department of Instrumentation and Materials Engineering, with Assoc. Prof. Dr. Suravut Chuangchote, a lecturer of Department of Instrumentation and Materials Engineering, Faculty of Engineering, and Assoc. Prof. Dr. Phatiya Khemachiwakul, a lecturer of Department of Environmental Engineering, Faculty of Engineering, being their Advisors.

“The starting point comes from our observations on the problem of energy use in buildings with glass as the main material such as office buildings or universities, which often have problems with excessive sunlight shining in, eventually forcing the curtains to be closed and the lights or the air conditioners turned on even stronger during the day to deal with the heat outside. We see that this is an inefficient use of energy even though the sunlight can be an energy source if it is managed efficiently. So, we bring these problems to consult with our Advisors in the Research Center of Advanced Materials for Energy and Environmental Technology (MEET) Research Group,” said Nganrungruang, a representative of the Team, about the beginning of the Project.

This innovation combines two important technologies: the “Electrochromic Film” that can control the transparency of the film in accordance with the electrical supply that stimulates the arrangement of the crystal structure in the material and “Solar Cell” embedded in the film that can convert the incident light energy into electrical energy for immediate use in the system. This film helps control the amount of light that passes into the room, reduces heat from infrared rays, thus saving on air conditioning, reducing UV rays that damage the skin and objects in the room, and also allowing light to shine in just as needed, while helping to reduce the use of light bulbs at the same time.

“We start to develop a small 1 x 2 square meter model by simulating the area used for installation inside the house and calculating the electrical power that the film can produce in 1 year compared to the use of various electrical appliances. The result is that this prototype film can produce electricity according to the standards of the cells used and reduce electrical energy consumption in the building by up to 22% per year. It can be said that the film can supply electricity to basic devices efficiently and has the potential to reduce the load on electricity from the main grid of the country. This film can significantly reduce energy consumption and electricity costs as well as generating electricity to supply small electrical devices such as LED bulbs”, explained Pikulkaew on the experimental process and the resulting impact.

The significant uniqueness of this smart film prototype is that it can be installed without any need to change the building structure. Users just simply inform the Team of the size of the glass they want to install, and the Team can design the film according to the actual size and produce it immediately. With the “Plug and Play” concept, users do not have to dismantle or adjust any additional electrical systems. It is suitable for target groups who want to see fast results and want to concretely change their buildings towards the way to use clean energy.

“Another thing that makes this innovation different from other general films on the market is its ability to “think and adapt.” The Team is developing the prototype into a full-fledged “Smart Devices” by embedding sensors to measure light intensity and temperature, as well as a processing system to detect activities in the room and automatically adjust the film’s brightness according to the time or type of activity, such as reading, meeting, or relaxing during the day. All these will allow the film to control itself in real time, intelligently responding to users in real life”, explained Chaikaew.

In addition, emphasis is placed on the “environmental friendliness” whereby materials easily recycled are selected. The modules of the cell panels are designed to be removable or disassembled when they reach the end of their lifespan without creating residual pollution and to help reduce the amount of electronic waste in the future. All these are in line with the “Net Zero Emission” goal that international organizations have prioritized.

Although this film is still in the prototype stage, the Power Maker Team has started to receive attention from entrepreneurs (from presenting their work at an event) and has set a goal to plan for further development and prepare to enter the patent registration process to protect the intellectual property. The Team is also planning for industrial production in collaboration with the private sector in the future to be able to respond to the market that wants to transition to clean energy and green technology.

“Another very important thing for us is learning together. We come from different Departments, so we must think together and work as a team. We exchange ideas and talk a lot to find a solution that everyone identically understands. The chance of practicing communications with our users, supporters, and Advisors, is indeed an experience that makes us feel like we are trying real work before encountering the real thing after our graduations”, said Pikulkaew.

Asst. Prof. Dr. Chuangchote and Asst. Prof. Dr. Khemachiwakul, the Project Advisors, absolutely agree that “getting to work on real problems and being able to develop innovations with potential to be further developed to the industrial level is a valuable experience. It not only helps improve the Team’s skills, but also creates their prominent profiles and helping students to be confident in entering the labor market and meet the needs of the industrial sector.”

Although this smart film is just still a prototype, nevertheless, it obviously reflects that if we give our new generations a chance to think and try, they will absolutely be ready to invent new things that are meaningful and help change the future of the world for the better.