SOCO Makes an Addition to New Smart Solutions for Bending Machines, Laser Tube Cutting Machine, in the EVs Manufacturing.

The metal parts inside an EVs are one of the most important parts of the EVs, whether it is the chassis, tubes or structures. For the reason that the use of the traditional metal cutting technology for these types of workpieces may not meet the needs of the manufactures of new era vehicles, SOCO therefore developed the machine solutions to be more potential no matter what it’s the cutting, bending work or laser cutting to make the machine a smart machine and respond to the needs of today’s EVs manufacturers.

SOCO Machinery Co., Ltd., is a Taiwanese-based machinery manufacturer with a factory in Taichung that accounts for the machines being dedicated solutions for every type of application: such as; Tube Laser Cutting, Sheet Metal Laser, Tube Benders + End Formers, Circular Saws + End Finishers. SOCO has global branches and global partners that aim to continuously improve and deliver the highest standards of machinery in terms of the efficiency, quality and service to manufacturing industrial sectors: such as; automotive, aerospace, construction, medical equipments, furniture and sports equipment, etc.

Mr.Kyle Lo, CEO and Managing Director, SOCO

Mr.Kyle Lo, CEO and Managing Director, SOCO

Mr.Kyle Lo, CEO and Managing Director, SOCO, said that, the automotive industry is focusing on the transition to Electric Vehicles (EVs). Over in the past year, EVs sales saw a steep increase and the market is projected to grow at a CAGR of 17.4% during the period of 2020-2027. It is also further projected that EVs and other vehicles will emit pollutants to be zero at 70% of the new vehicle sales by 2040. In this connection, SOCO Machinery is ready to provide supports to manufacturers in taking advantage of this new wave of technology, especially, tubular components that have been modified for compatibility with EVs: such as; cooling system for battery, tubes support and guides for electric wiring, roof support frames and compact HVAC systems because EVs need to have a reduced count of metal parts and trend on weight reduction and EVs’ structure mass to be of lightweight coupled with the fact that the world over has placed the importance to the global greenhouse gas emission regulations.

SOCO Develop Machines to Suit the Industry 4.0 Productions.

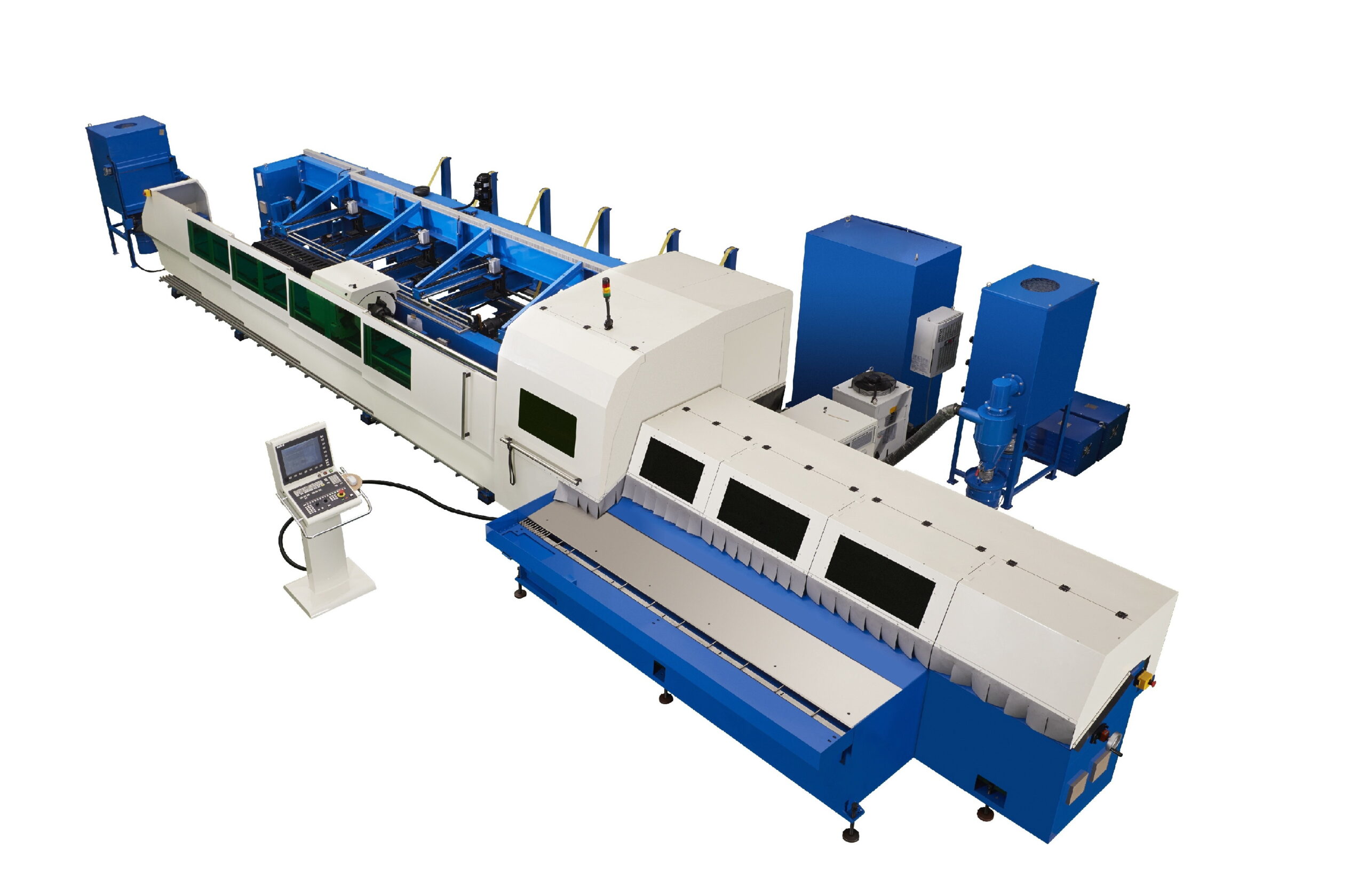

Respective to the machines that we would like to present to our customers consist of the SLT-152 FIBER 3D model tube laser cutting machine a fully automatic tube cutting fiber laser technology that can perform straight or bevel cutting up to 45 degree in different profile shapes with the capacity up to OD 152 mm which is suitable for cutting tubes of different profile shapes for the automotive applications: such as; impact beams, bumper beams, roof supports, control panels, etc. Another model is the SLT-ROBOTCUT which is absolutely suitable for cutting pre-bent tubes, pre-formed parts or irregular workpieces. The cutting rate and speed can also be adjusted according to the thickness of the materials and the laser power can as well be adjusted in different levels by using smart CAD-CAM software that can import 3D files and automatically translate them into cutting paths for applications in the production work: such as; car bumpers, car body, control panel, and impact beams.

SLT-152 FIBER: Tube Laser Cutting Machine

While SLT-102 model is a tube laser cutting machine that joins multiple machining processes into one system at the automated production line, creates automated production lines, integrates chamfering, deburring, length measuring, and stacking. The cutting process can be easily monitored with SOCO i2 control software and there is an automatic loading system available together with the material alignment for applications in the automotive work: such as; impact beams, car body, chassis cross bars, control panels, etc.

Electric tube bender + left and right of SB-32X9A-2S-V-U model is yet another machine capable of left + right bending in a single process, fully electric up to 8 axes, easy to program and set up, integrates the tube bender with Automatic Loaders (AF, AFM, Robots) and Automatic Unloaders (AUL, ROBOTS) that come along with SOCOi2 control software and operation interface on the automotive applications, i. e. stabilizer tubes, car seat frames, headrests and steering systems, for bending mild steels, stainless steels and aluminum.

In addition, we have a passenger compartment frame and chassis bender of SB-130x6B-3SV/SB-131X11A-MRV model the CNC tube bender that includes Roll, Booster and Draw Bending which is highly accurate and repeatable in one process. Moreover, we can offer the customized tooling solutions for a wide variety of tube profile modifications controlled by SOCO i2. The bender can also perform the intuitive programming and advanced simulation, automation and Industry 4.0 real time feedback functions for the automotive applications: such as; cabin frames, car body, chassis, impact beams and bumper beams.

SB-22X8A-2S-V-U Tube Bending Cell

Mr. Lo further added that, SOCO also has a control system so called SOCO i2, which is an advanced production management solution to correspondingly conform to the real Industry 4.0 standards whether it is on the aspect of the inspection of your production which can be monitored from any place and at anytime, the automatic compensation being interfaced with CMM measuring system, real time production reporting including CMM measurement system and IRMS a remote monitoring system + interaction and real time production diagnosis.

In Thailand, SOCO has a distributor: namely; Thaisakol Group Co., Ltd. with knowledge, expertise and familiarity with SOCO machines for many decades. We fully hope that the customers will be satisfied with our fully comprehensive after-sales services for SOCO brand machines.