Taiwan Machine Tools : Driving Thailand 4.0 with Precision Smart Manufacturing

Leading brands power Southeast Asia’s manufacturing transformation at METALEX 2025.

[Bangkok, Thailand] – As the Thai government vigorously implements the “Thailand 4.0” initiative and the Eastern Economic Corridor (EEC) plan, the manufacturing sector is rapidly moving towards automation and intelligence. This year, the 39th METALEX 2025 is set to be a focal point, gathering global top-tier brands to showcase the latest advancements in metalworking and smart manufacturing.

Taiwan, as a globally significant machine tool exporter, is highly attractive in the ASEAN market, thanks to its capabilities in high-precision and high-flexibility manufacturing. This year, leading Taiwanese manufacturers, including PALMARY, SUN FIRM, QUASER, and CHI ZONG, will exhibit their cutting-edge innovations, injecting new highlights into the event.

PALMARY: Extreme Grinding, Boundless Precision

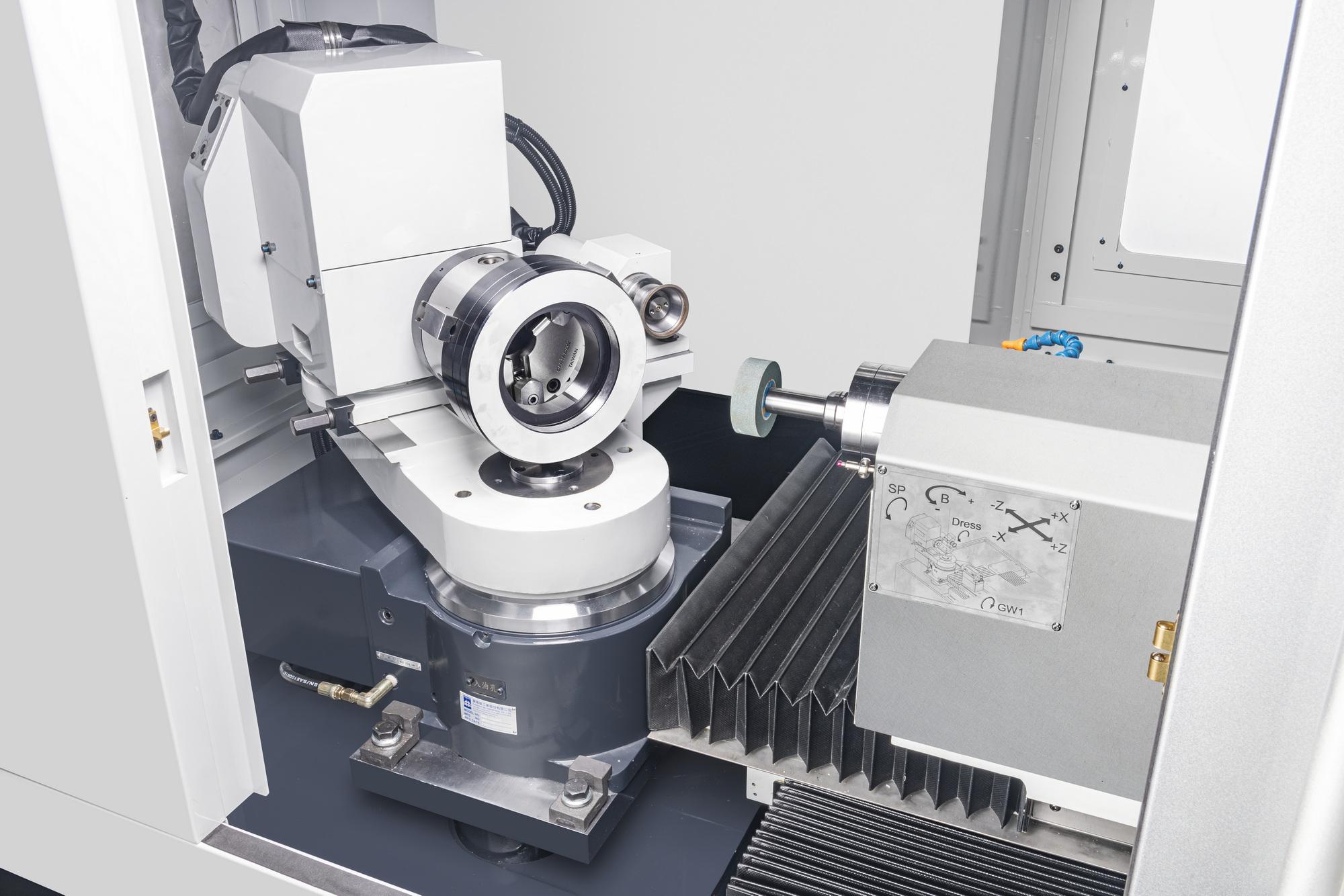

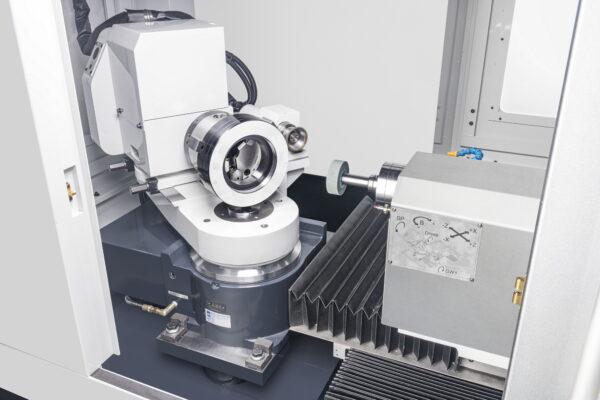

Renowned for its profound expertise in grinding technology, PALMARY will highlight its flagship OIG-200R High-Precision Internal Grinding Machine. Equipped with a CNC control system and automatic compensation function, the OIG-200R can be integrated with automatic measuring systems such as the Marposs for smarter and more stable grinding processes. To meet the demands of production line automation, the OIG-200R is optionally available with an automatic loading/unloading module, facilitating unmanned, continuous production during nighttime shifts.

Another key product is the X-2540A Series CNC Angle-Head Cylindrical Grinder. Focusing on high stability and high efficiency, it features a cross-type slide table and an enhanced guideway design, which not only boosts precision and rigidity but also effectively reduces the machine’s footprint, making it ideal for production environments with limited space. The entire machine is equipped with a user-friendly intelligent operating interface and a fully enclosed protective design, prioritizing safety, aesthetics, and operational convenience.

SUN FIRM: Leading Heavy-Duty Smart Manufacturing with a Full Product Line

With over 65 years of professional experience, SUN FIRM has been one of the famous lathe brands in the industry. SUN FIRM delivers the most comprehensive product line of CNC lathes in Taiwan, ranging from precision to super-large heavy-duty cutting CNC lathes. It is one of the few global manufacturers with complete lathe integration capabilities. SUN FIRM’s core strategy is to satisfy the extreme processing requirements, which are often being requested by industries in Energy, Mining, Aerospace, Shipbuilding, and Heavy industry sectors, establishing market leadership through its impressive processing range.

For Horizontal CNC Lathes, the swing over bed ranges from 500 to 4,000 mm, with distance between centers up to 20,000 mm, and a maximum load capacity of 40 metric tons. The Slant Bed CNC Lathes, designed for heavy cutting, offer a swing over bed up to 1,160 mm, while the maximum turning diameter on the worktable for Vertical CNC Lathes extends from 1,250 mm to 4,000 mm.

From product selections covering “1-meter to 20-meter machining capacity” to providing high-torque spindles and high-rigidity bed designs, SUN FIRM demonstrates profound strength in heavy-duty cutting and high-precision machining. With superior technology, shortest delivery time, and bespoke design-and-manufacturing capabilities, SUN FIRM continues to elevate Taiwanese precision CNC lathes onto the global stage, making it an optimal choice for international clients seeking a competitive edge.

QUASER: Precision 5-Axis, Green Manufacturing Through Smart Tech

QUASER continues to specialize in the high-end 5-axis machining field, spotlighting the MF700 5-Axis Simultaneous Machining Center. This center is characterized by high precision and high stability, making it suitable for aerospace, automotive, and complex component manufacturing. The company maintains consistent precision through fully air-conditioned production facilities and adheres to a rigorous quality management and R&D system, with stringent checks from design modeling and Finite Element Analysis (FEA) to actual machine testing, embodying a “Precision and Stability” manufacturing spirit.

CHI ZONG: Ushering in a New Era of Cordless Lifting

CHI ZONG introduces innovative battery technology for portable hoisting solutions, including the DCH-250/500 Battery Chain Hoists and the DCW Series Battery Winches, realizing the concept of “Cordless Lifting.” These devices combine lithium battery power with a lightweight design, allowing for operation in any environment, eliminating power restrictions, and enhancing mobility. All products are designed according to EU CE standards, passing 125% load testing and rigorous inspection to ensure maximum safety and stable performance.

As the wave of smart manufacturing advances, the Taiwanese machinery industry is collaborating with the ASEAN market to create a new manufacturing landscape through innovative technology, precision craftsmanship, and flexible manufacturing energy

.

We cordially invite you to visit the Taiwan Pavilion to learn more! Taiwan Pavilion Booth Number: BM09 @HALL 102 BITEC.

เราขอเรียนเชิญท่านมาเยี่ยมชม Taiwan Pavilion เพื่อเรียนรู้เพิ่มเติม! ได้ที่บูธ : BM09 @HALL 102 BITEC.

For more information about the Taiwan Pavilion activities, please visit the official event website: https://www.taiwanpavilion-twmt.tw/METALEX-2025/index.html