The Story of “Parameters” in Automatic Machinery and Computer-Controlled Machines

In CNC machines or other computer-controlled machines, we often hear an English word, “parameters”, which literally means “variables” or something that must be changed to achieve optimal performance. (Variable means changeable, or it may not have to remain the same).

Parameters are divided into Machining Parameters (which the user can change according to the task) and Machine Parameters (that some brands and types of machines may be divided into System Parameters and User Parameters). User Parameters can be changed by a higher-level machine operator, but System Parameters should only be changed by the manufacturer, distributor, or someone with the “proper experience).

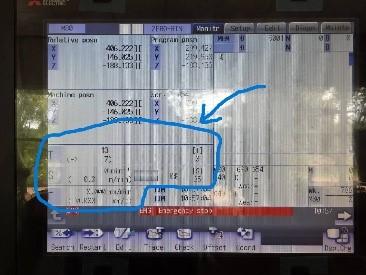

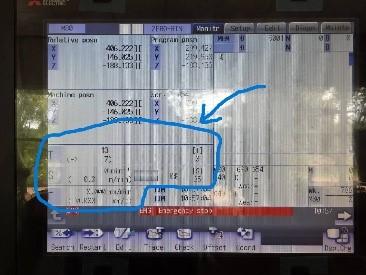

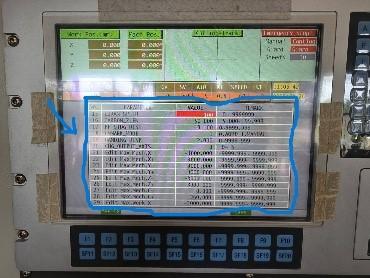

Image showing Machining Parameters CNC Machining Center Mitsubishi CNC

Image showing Machining Parameters CNC Machining Center Mitsubishi CNC

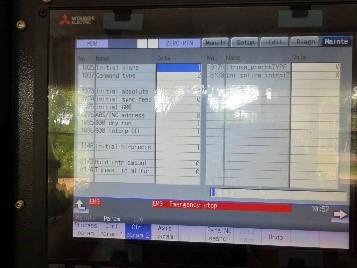

Image showing Machining Parameters CNC EDM Joemars EP Series

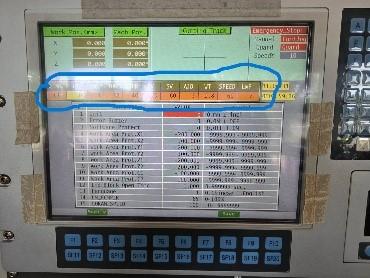

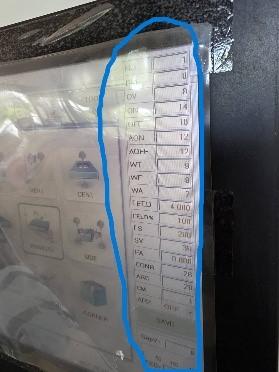

Image showing Machine Parameters (User) CNC EDM Joemars EP Series

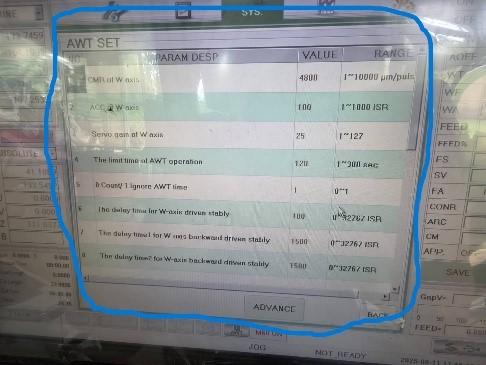

Image showing Machining Parameters Wire Cut Joemars AWTxS Series

Image showing Machine Parameters (User)Wire Cut Joemars AWTxS Series

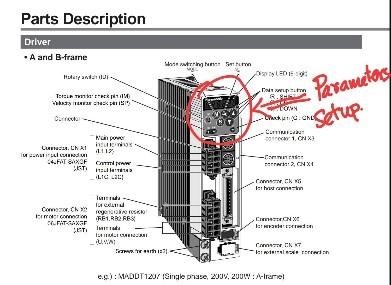

Even in Servo Drives for driving various axles….or Inverter Unit for controlling motor speeds…or various relative moving parts that are related to each other, we will have Parameters to adjust, change, and modify…to make them work together with other parts to produce results according to the characteristics of that machine…which should be classified together with Machine Parameters because they do not have to be adjusted and changed according to the work each day.

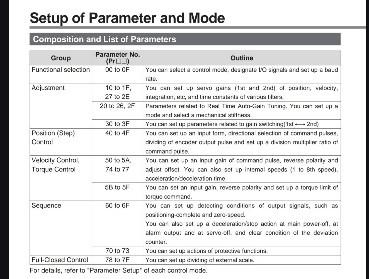

The picture shows the Parameters input or Setup Parameters section of Panasonic Servo Drive.

Machine parameters don’t require the user to adjust them every day, even with daily changes in the workload,or with every job involving different materials, types, and sizes of cutters and drills because these parameters define the relationship between the controller and the machine, or mechanical components may not be in the condition to change daily. If they should do, they would become unusable, damaged, or have problems that make them unusable, for example: if lubrication is poor, oil is not available, oil line is broken or damaged for a long time, it would cause the shaft moving resistance to be high, the machine parameters that determine the shaft drive would be incorrect and unsuitable which would eventually cause an unusual shaft drive and could possibly trigger an alarm as the manufacturer has esigned as to how users could be notified in order to communicate with them and make them understand about the machine.

Another parameters that the users need to make changes every day, with every job, every material, program, or cutter… are the changes in the feed rate, spindle speed, depth of cut, even the direction and the strength of the coolant chip injection…These are parameters also called Parameters, but they are Machining Parameters.

To give a visual example, such as a car in Italian language, which is called “Car” in English, can be called a Machina.

Engine and suspension modifications are parameters that such car driver need not require to make any adjustment or cannot adjust daily in a timely manner. We can compare them to the Machine Parameters. Whether a driver has pressed the accelerator hard or soft, used the clutch, brakes hard when approaching a stop, causing passengers’ heads to hit the car parts, or softly applies brake before the stopping point to achieve a smooth stop, these are all parameters that the driver can change while driving. We can compare them to the Machining Parameters.

By now, readers who have been thinking all along with me should be able to distinguish the machine parameters and the machining parameters.

Machine parameters determine how a machine will behave. Before a CNC control is installed on a machine, the default values from the CNC manufacturer are the same. However, when it is installed on a machine with different movement mechanisms, different axis travel sizes and distances, different axis drive motors, different servo drives, even the same model, but with different drive capacities, different spindle motors with different power capacities, different rotational speeds, and different spindle power transmission methods (e. g., gear drive, belt drive, inline coupling, or direct drive) (all of these are determined by the manufacturer’s machine manufacturing policy), etc., the machine manufacturers must adjust the parameters to suit the specific machine manufacturer and model and the machine must be tested to ensure its proper performance according to the specifications stated when it is offered for sale (usually in the Catalogue).

Why do we need to change all these Machine Parameters? Shouldn’t it be the manufacturers’ responsibilities? Of course, Yes, the manufacturers would be the party to make the adjustments.

However, the nature of work that must be correct when we are machining on such machine, cutting tools, milling cutters, work holdings, positions, and areas of machining may vary. When the same machine is used for machining, the age of the machine, the condition of the machine’s mechanisms when time has passed over, lubrication efficiency, maintenance, and user care, etc., all have the influence over the need for machine parameters to be changed, whether more or less. When changes or adjustments should be needed, they would be needed to be done if work output being used to be accurate and precise has become to be apparently erroneous or mistake thereafter no matter what such error has started from a minor to severe one to the extent of exceeding the permitted error levels. (Actually, when value of the machining result has altered, investigation should be conducted to determine what the cause is). The distributors shall be responsible for that. If machine owners can handle the issue by themselves, they must carry on the investigations to determine the root cause and adjust those Machine Parameters to prevent them from escalating into bigger problems in the future…

To change Machine Parameters, you must access a system that usually has a password. (It’s not 100% forbidden that they are unchangeable, but passwords should be there for thought, deliberation, and restraint to prevent random guesswork…because from what I’ve seen that everyone knows the password or has asked for it without anyone holding it back…in my opinion).

In most case, service technicians often adjust Machine Parameters over time, depending on the nature of machine usage in each day, whether heavy or light, or when there has been an accident, collision, or rough machining to what extent which is called Backlash Compensation of each axis (in case where the output is incorrectly sized or the positioning appears slightly off from the specified value after a long period of normal use).

During the “Preventive Maintenance”, backlash compensation settings for each axis should always be adjusted. Quite often, if your machine is sightly malfunctional which is not obviously apparent, this adjusting backlash compensation will enable you to reveal cause of the problem. After the adjustment and sometime after using, you may notice the emergence of the issues such as loose gibs in the machine to be a box-way slideway, a faulty or damaged coupling between the motor shaft and ball screw, a lack of lubrication, and an inconsistent coefficient of friction throughout the slide or axis movement, etc.

The language used herein is not formal, like that of an academic textbook. If you don’t understand it after reading, reread it. It is advisable that you try to re-arrange the paragraphs for rereading, it may make you more understandable. If you still have anything in doubt, or any suggestion may have please contact author @ 084-757-6663.