“THERMATEC” – 100% THAI-BRANDED MACHINERY… USED AND MADE BY THAIS, INTERNATIONAL QUALITYSTANDARDS GUARANTEED.

Producing Thai-branded products is crucial for economic recovery, strengthening industries, and enhancing the country’s competitiveness. This is achieved by integrating Thai ingenuity, available materials, and culture with innovation and international standards to create a unique identity, build trust, and add value, enabling competitiveness both domestically and globally. Ultimately, this drives the overall economic and cultural growth of the country.

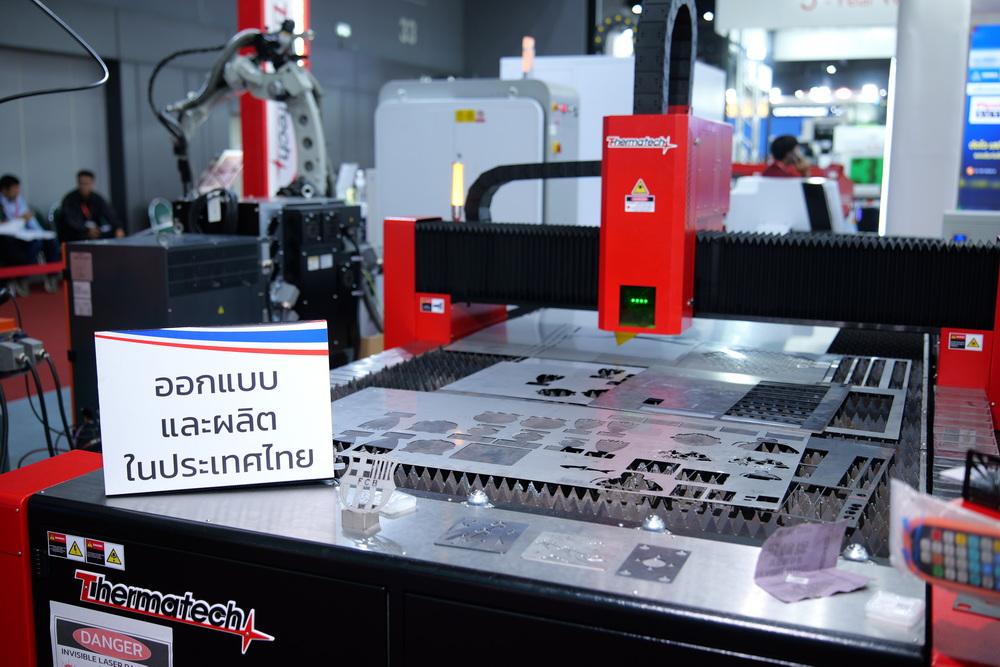

Thermal Mechanics Co., Ltd., specializes in the sales and the after-sales service of CNC cutting machines using gas and plasma cutting processes, fiber laser cutting machines, all types of electric welding, automated welding equipment, orbital welding machines with pipe cutting and notching machines for joint preparation, spot welding machines and accessories, as well as sheet metal processing machinery.

Mr. Ekawee Vaitoonkiat, Managing Director of the company, gives his explanations that Thermal Mechanics is an expert in manufacturing machinery for metal cutting and automation systems. We have been in this business for 22 years as a distributor and manufacturer. Our machinery is under the “Thermatec” brand, and we are well-known for our fiber laser machines used in metal cutting. We have 7 years of expertise in this type of machinery, with continuous developments for higher cutting power. Initially, we developed machines with a cutting power of 1,500 watts, but currently, our cutting machines have a maximum power of 30,000 watts, capable of cutting steel up to 70 mm thick and stainless steel up to 60 mm thick. Meanwhile, we have developed two models of machines: one for cutting sheet metal and the other for cutting pipes. The sheet metal cutting machine can cut sheets and pipes with a width of 3.5 meters and a length of 14 meters. These developed and manufactured machines are produced in Thailand by Thermal Mechanics Co., Ltd., under the “Thermatec Brand” and have always received good feedbacks from Thai businesses in terms of the craftsmanship, quality standards, and the after-sales service.

“Our strength is that we can upgrade the performance of the machines. When customers use them and want higher production, we can help them by sending our engineers to assess where upgrades are possible, or when there are areas where technology can be added to help, such as customers using 3,000 watts upgrading to 6,000 watts, or customers with 6,000 watts increasing to 12,000 watts, etc. This allows customers to avoid new investment and saves space by utilizing the existing machinery, which will significantly reduce their investment costs.”

Thermatec – 100% Thai Brand.

Mr. Vaitoonkiat goes on adding that “as a Thai brand, we have seen increased acceptance from Thai entrepreneurs in recent years. The obstacle for us as a Thai brand is that we cannot compete on cost with large foreign manufacturers. Therefore, we find ways to differentiate ourselves and build customer confidence. What we have added is functionality and structural strength, or other aspects that make customers feel that there is a difference. Currently, our customers are increasingly accepting us. We really want them to come and discuss the in-depth details of the machine’s usage because it will allow us to produce precisely what is needed and at the most cost-effective price. Currently, the “Thermatec” brand has approximately 80 machines in use in the industry, and the even break point for a fiber laser cutting machine is 2 years, and it can be used for more than 5 years. In terms of spare parts stock, we have sufficient stock for our customers.”

Mr. Vaitoonkiat finally makes his conclusion by saying that fiber laser machines are currently in high demand in the metal industry. Therefore, I would like to encourage people to open their minds to try the products of Thai manufacturers. This will not only support Thai producers but also contribute to the overall national economy, including job creations and supply chain linkages that circulate money within the manufacturing sector. It may also inspire other manufacturers to create Thai brands that meet international standards to gain global recognition in the future.