First-ever Look Inside Bangkok Cable’s Advanced Cable Manufacturing Plant Thailand’s No.1 Market Leader in Cable Production Capacity

In a world where energy is the backbone of every system, electric cables function as vital arteries, driving the flow of life in every corner from homes and offices to industrial plants and national infrastructure. High-quality and reliable cables are therefore more than just an investment; they are a matter of national stability, directly tied to safety, economic development, and the well-being of citizens.

Recognizing the crucial role of quality cable production, Bangkok Cable Co., Ltd., a trusted name for over 60 years, has grown from a family business into Thailand’s market leader, with over 30% market share as the highest in the country. Recently, the company opened the doors of its main manufacturing plant in Chachoengsao to members of the media offering a rare glimpse into the cutting-edge production process for the very first time.

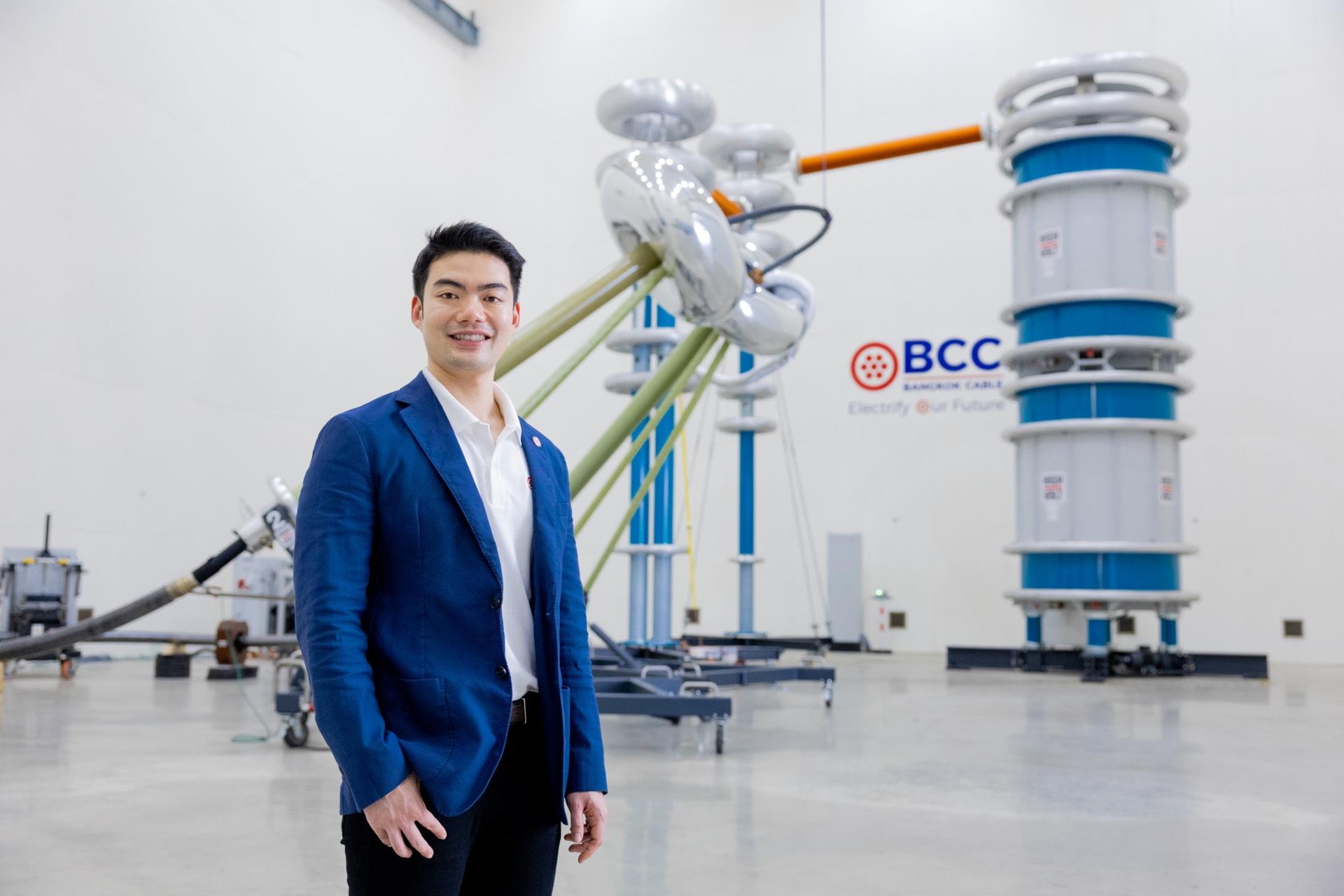

Mr. Pongsapak Nakornsri, Chief Commercial Officer of Bangkok Cable Co., Ltd. (BCC), revealed that Bangkok Cable currently employs more than 1,250 people and operates three manufacturing sites, including the Samut Prakan plant, the Chachoengsao plant, and the Operation and Innovation Center its third facility located on the Chachoengsao site, making the total area of Chachoengsao facilities spans over 251 rai (99 acres). These plants have a total cable production capacity of over 60,000 tons per year, encompassing more than 80 product types.

“Since late 2022, as the COVID-19 situation subsided, our overall production capacity has increased by over 30% annually. We now hold the position as Thailand’s largest cable manufacturer in terms of capacity. In 2024 alone, we delivered over 50,000 tons of cable, equivalent to more than 400,000 kilometers in length reflecting the continued expansion of infrastructure and industrial sectors,” said Mr.Nakornsri.

The Chachoengsao factory serves as the company’s primary manufacturing site, covering the entire production process with globally recognized quality standards. The production of a single cable involves seven main stages, including Raw Materials Selection, Copper & Aluminium Rod Production, Stranding Process, Insulation Process, Multicore Assembly, Protection Enhancements, Sheathing & Labeling. Each step is carried out with meticulous attention to detail for example, sourcing copper from Chile, the world-renowned producers country, and conducting stringent quality inspections on every cable produced.

Mr.Nakornsri emphasized that Bangkok Cable is a leader and pioneer in many energy-related fields. The company was the first in Thailand to establish a Fire Testing Lab in 2000, certified under TIS 17025 (ISO/IEC 17025), marking a significant milestone in setting industry benchmarks for cable testing and quality certification. Most recently, the company has also established an Extra High Voltage Lab to test cables up to 230 kV, suitable for major infrastructure and mega-projects.

“This lab can simulate electricity usage at 700 kV and current up to 6,000 A to ensure that every cable we produce meets engineering-grade accuracy and safety. Nationwide, there are only two such labs, and ours is the only one operated by a Thai manufacturer. We continue to push the boundaries of technology and innovation within our factories as part of our transformation into a Smart Factory 4.0,” said Mr.Nakornsri.

He further added that the company’s commitment to quality is not limited to the factory or laboratories it is ingrained in the corporate culture. This includes staff training, data analysis tools development, and designing cables tailored for real-world applications in homes, factories, high-rise building, and even national infrastructure projects.

Importantly, the company is deeply committed to sustainability and minimizing environmental impact. As one of the pioneers in the transition to clean energy, BCC established its affiliate, Bangkok Solar Power Co., Ltd., to spearhead and develop clean energy projects in Thailand. In 2006, the company built Thailand’s first solar power plant within its Chachoengsao facility. Today, BCC has expanded its solar installation across the factory grounds, with solar energy now covering over 50% of the total production capacity across all three plants. This initiative aligns with the company’s mission of “Safety for People, Safety for Cities, Safety for the Environment” and underscores BCC’s key role in connecting Thailand to a greener future. Today, Bangkok Cable’s product portfolio spans low, medium, high, and extra high-voltage cables, bare wires, solar cables, control and signal cables, electronic wires, and telecom cables. It also includes flame-retardant products and those certified under the Green Label scheme, meeting modern demands for safety and environmental sustainability.

As Thailand accelerates its journey toward clean energy, renewables, and smart cities, electric cables will play an increasingly pivotal role. And Bangkok Cable stands ready to serve as the lifeline of Thailand’s energy grid not just powering connections, but anchoring trust, safety, and a sustainable future for generations to come.