Expertise in grooving for small part production Walter Cut DX18: New parting off system with lateral clamping for long centre lathes

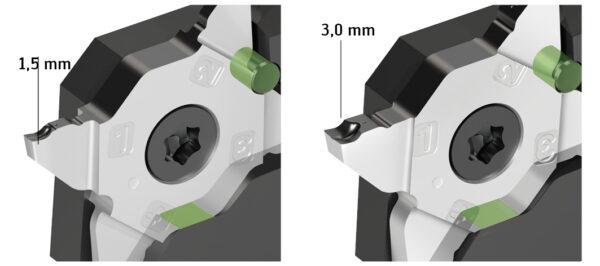

Walter Cut DX18: The patent-pending positive engagement prevents incorrect fitting, especially with narrow insert widths.

Grooving processes play an important role, especially in mass production. The trend towards miniaturisation of even complex component geometries is one of the driving forces, especially in the field of parting off and grooving tools.

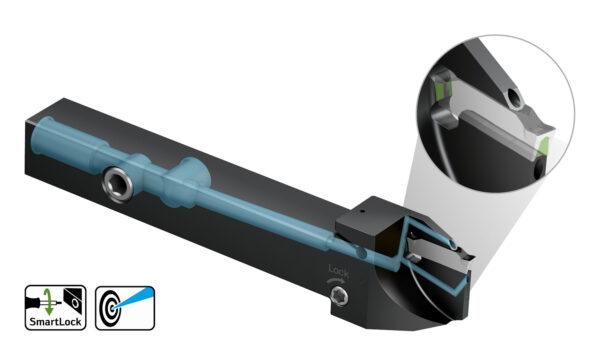

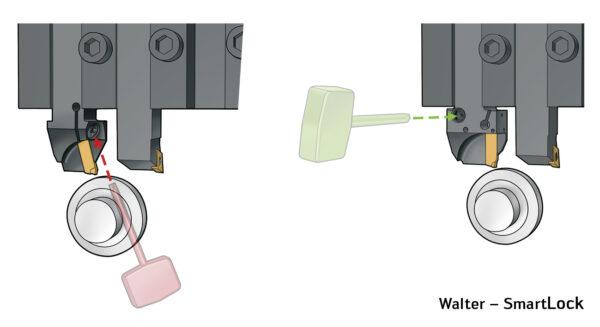

With Walter SmartLock, the clamping screw is located on the side of the tool. This allows the indexable insert to be changed quickly and easily, especially on long centre lathes and multi-spindle machines.

Conquering the conservative market with innovative solutions

The parameters, according to which the decision for a parting off process and the corresponding tools is made, are machine run times, tool life and process reliability. Typical problem areas, especially for machining operations in which you are grooving deeper into the workpiece, are the stable fixing of the indexable inserts, chip breaking, and cooling. Users who want to play it safe therefore reduce the cutting data below the recommended values. Who wants to risk stopping the production process due to chip jams, a vibrating tool or even if a cutting edge breaks?

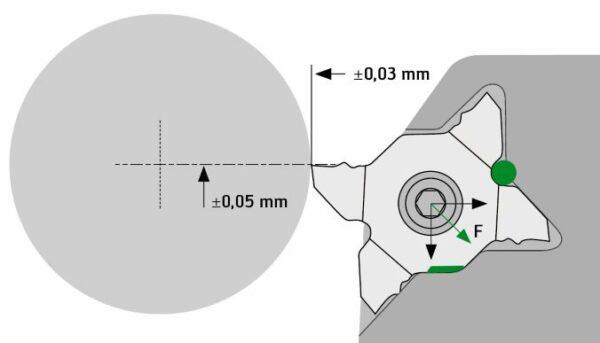

Self-aligning, highly accurate tangential screw clamping ensures optimal force absorption and user-friendliness.

This is exactly where the Walter grooving experts come in: With its portfolio of grooving tools, Walter already covers a wide range of grooving applications. Walter Cut DX18 is a double-edged system for grooving and parting off especially on Swiss type auto lathes or multi-spindle machines.

Walter Cut DX18 maximum stability and convenient changeover thanks to SmartLock

The Walter DX18 system is suitable for parting diameters of up to 35 mm. With the innovative, patent-pending positive engagement system, Walter’s developers are addressing the fundamental problems of narrowly dimensioned parting off tools: The stability and handling of the cutting insert. In conventional screw clamping, the cutting forces act in such a way that the existing clamping forces are not sufficient with negative effects on machining quality and process reliability. In contrast, the new Walter Cut DX18 cutting insert geometry locks the insert securely via positive engagement. Another innovation is the SmartLock system, which considerably simplifies insert changeover. With conventional screw-clamped systems, the machine operator has to remove the entire tool for this purpose and this in cramped and not always user-friendly, “oily” machine conditions. With the Walter SmartLock system, the clamping screw is located on the side of the tool: Simply insert the screwdriver, unscrew and change the indexable insert. Thanks to the positive engagement, the new cutting insert adjusts 100% correctly, even with very narrow insert widths.

The potential of the system was successfully proven in a tool life test on a Swiss type auto lathe. An outer diameter of 12 mm was parted off from 1.4057 material. The cutting edge width used was 2 mm. Markus Stumm comments: “With the new double-edged Walter Cut DX system, we were able to more than double the tool life compared to the single-edged competitor with maximum process reliability and productivity. The customer particularly liked the fact that they no longer had to remove the tool for changing the insert.”

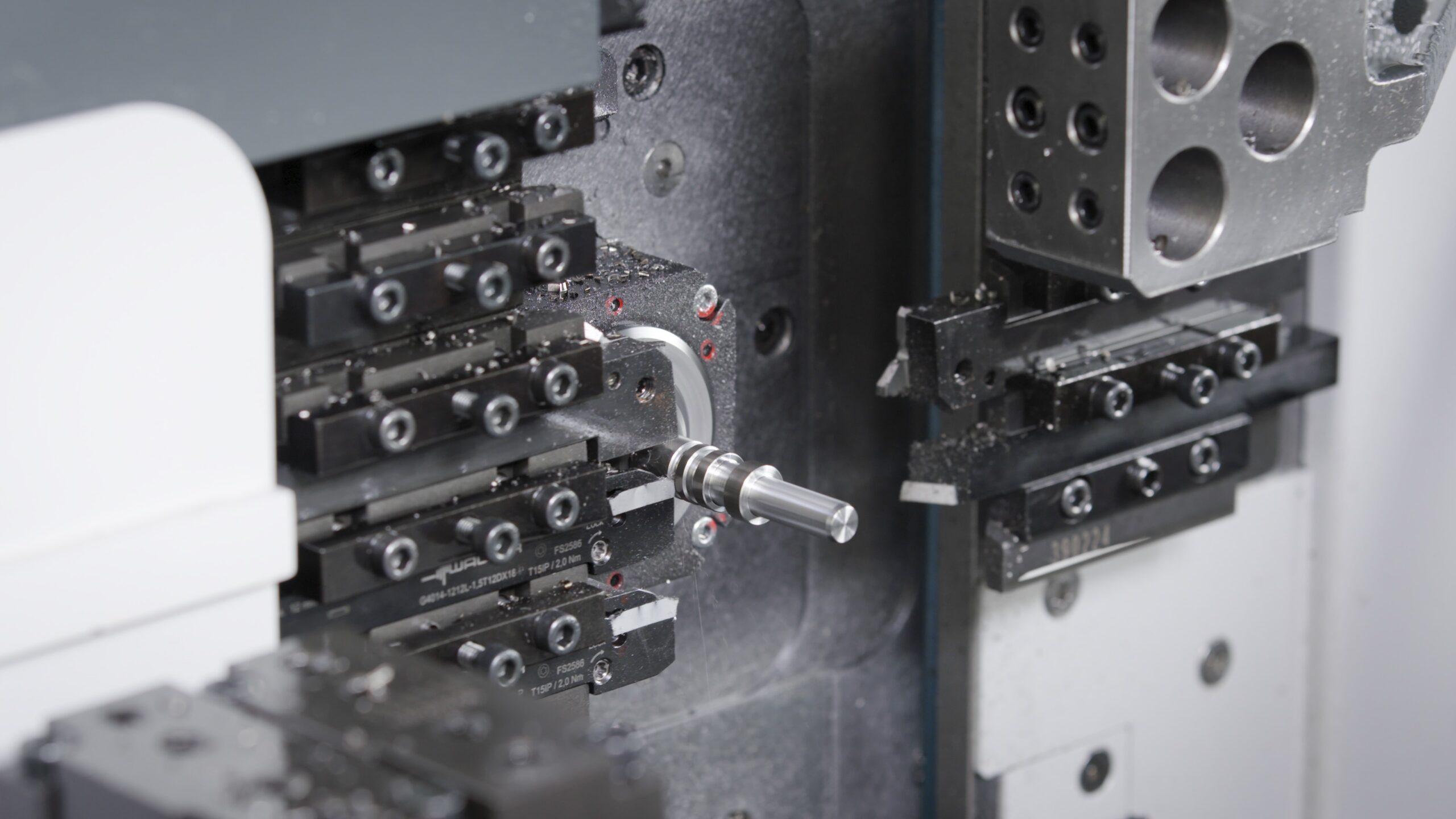

G4014-P/DX18 grooving and parting off tool used on a Swiss type auto lathe.

Process reliability in focus: Walter Cut GX and MX systems

The new DX system is the latest example of the Tübingen-based machining expert’s high capacity for innovation in the field of grooving and parting off. With the double-edged Walter Cut GX34, the development engineers have already shown the optimisation potential that lies in targeted technical improvements. In the meantime, the system has established itself as a reliable problem-solver for parting off diameters up to 65 mm. For example, a well-known customer from the automotive supply industry repeatedly experienced major problems with process reliability when parting off drive shafts (nitriding steel, dia. 60 mm). Markus Stumm and his team were given the opportunity to bring the double-edged Walter Cut GX34 system onto the machine. Thanks to its design optimised for the stability of the long cutting insert, the Walter system significantly reduced vibrations that previously occurred during machining. The feed during parting off could therefore be increased by 30% and the tool life quantity doubled. A further economic advantage resulted from the double-edged grooving insert instead of the single-edged competitor.

Stable, wide contact surfaces in the toolholder, regardless of cutting width, ensure low tool costs.

The Walter Cut MX with four cutting edges has proven to be particularly reliable, highly accurate and cost-efficient for the production of small precision parts up to a cutting depth of 6 mm and insert widths from 0.8 to 5.56 mm: The self-aligning, tangential clamping of the system and the dowel pin location in the insert seat lead to greater repeat accuracy, stability and process reliability. The special insert geometry also ensures that the inserts cannot be fitted incorrectly. During a tool life test in a large-scale production on a Swiss type auto lathe, the system impressed with a significant improvement in tool life. The task: Parting off precision stainless steel pipes with an outer diameter of 5 mm from 1.4301 material. The cutting width used for this is 1 mm. The result: The tool life could be more than tripled and all this with absolute reliability.