Unmanned Aerial Vehicle (UAV)… Thai Craftsmanship Ready to Enter into Commercial Productions.

MARCUS-B is a collaboration between the Royal Thai Navy Researchers, SDT Composites and Oceanus R&D. It is a fixed wing UAV using an electric motor for vertical takeoff and landing and both electric motor and fuel oil engine can be used for aviation travel with a takeoff weight of approximately 50 kg, normal travel speed ranging from 90-100 km/hr., and Pre-Preg Carbon Fiber material is used for making the whole aircraft body. The advantage of MARCUS-B is its structure and shape designed to be able to carry a maximum weight of not less than 60 kg., which means that, in reality, MARCUS-B will not be just a UAV for installing surveillance cameras for reconnaissance missions only but also give a flexibility enough to be able to deploy payloads for a variety of missions, even being armed. A structural modification for installing different equipment has neither been a problem because the structural design and assembly of all parts are made by the thoughts, skills and efforts of the entire Thai Team.

The first MARCUS received research funding support from National Research Council of Thailand (NRCT) with a period of time spent for conducting the research from 2019 to 2020. During the period in 2021, it was tested and demonstrated to user units and senior commanders in the Royal Thai Navy and presented for research work accreditation from the RTN Military Equipment Standardization Committee (MESC-RTN) where the MESC-RTN standard on which was recognized in 2021, but with a suggestion that if it were to be put into production line, it would likely need to be developed and improved to have a longer flight time for approximately 2 hours, at least. That was a background of a coming about for the ongoing project which the RTN has offered to request for the research funding support from NRCT in developing MARCUS-B project which according to such guideline, if MARCUS-B can fly for a longer time than that of the first MARCUS model, it can definitely be put into the production line.

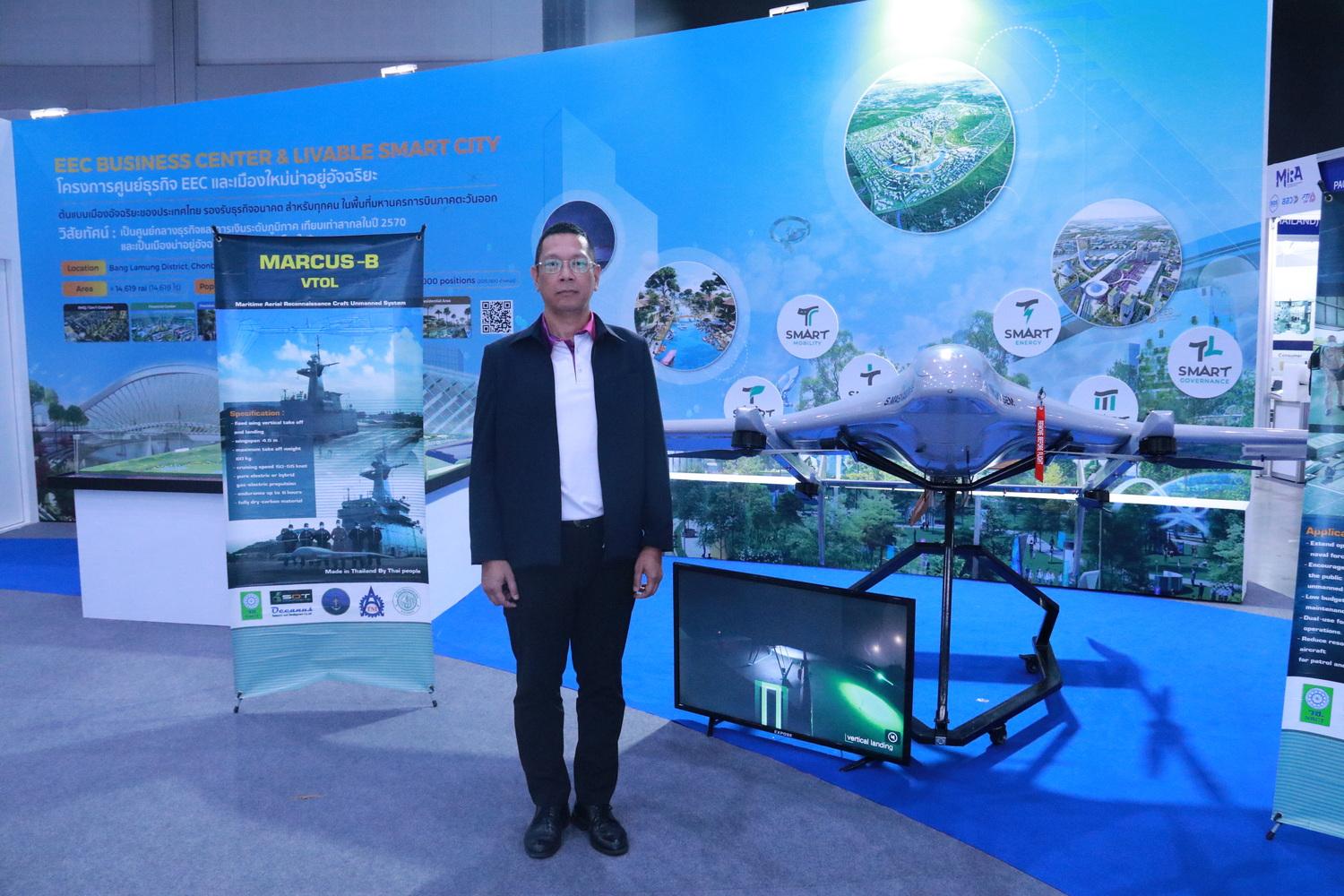

Navy Captain Panupong Khoomcin, Head of Researcher Team for MARCUS-B Maritime Aerial Recconnaisance Craft Unmanned System Type-2 revealed that, we are the Naval and Maritime Innovation Center of the Royal Thai Navy with our work achievement will be used as a prototype of UAV receiving supporting budget from National Research Council of Thailand (NRCT) currently on the second version or so called “MARCUS-B”. RTN will carry on the development of this work achievement on the integrated budget which we have received from EEC to support further development and research of MARCUS-B. The objective of the Naval and Maritime Innovation Center of the Royal Thai Navy is to bring the MARCUS-B research results collaborated with educational institutes and the private sector for the production of an industrial prototype. To begin with, the developed MARCUS-B will be used in the RTN activities first and initially we have already developed a plan to produce. Basically, it will be used for patrolling islands and border areas of neighboring countries and the RTN is considered to be the first customer of this work achievement. We also have a development plan for further commercial productions.

The challenge of creating a MARCUS-B is our Working Team’s desire to place the emphasis on MARCUS-B to have its own unique identity that it must have a shape variedly different from UAVs being commonly seen. Its performance as an unmanned aerial vehicle may not be at its best when compared to other shapes, but our Working Team wants to communicate that its design is copied from the shape of a seagull that can often be found in coastal areas, that it is a fixed-wing aircraft specifically designed for vertical takeoff and landing, that it can fly in the air not at a very high speed to cope with gusty winds which are normal conditions along the coastline and at sea. But most importantly, we want to show that it is a design work achievement and that all construction steps are taken place in Thailand by Thai people.

The main components of MARCUS-B that still need to be imported from overseas meanwhile are likely to be a group of Pre-Preg Carbon Fiber fibers where the production resource of which has not yet been in Thailand, so, they need to be ordered for import from England and must be kept at -20 (minus twenty) degrees Celsius throughout the transport period. Motors and electronic circuit boards including surveillance cameras and communication systems have still been under the limitations likewise those of other manufacturers which still rely on the imports from abroad. It is also not cost-effective to build a production line in Thailand. Thus, MARCUS-B opts to use these elements mostly from China and other countries in the nearby region. (But that is not a restriction though, MARCUS-B can still install other systems and equipment from production sites all over the world). However, other components such as the main rotor, could eventually be sourced out by the Team of Researchers that can work together to develop from within the country. Forming every part of the structure, efforts and skills, in assembly, installation, and adjustment of various settings have entirely come from the skills of Thai people within Thailand which is what the Working Team has their intentions on and wanted to be such that perpetually, that they want MARCUS-B to be a work achievement Made in Thailand by craftsmanship of Thai people as much as much as possible.