Let’s Meet 3 Leading Machinery Manufacturers from Taiwan!

About Taiwan Excellence Awards

The Taiwan Excellence Awards were established by the Ministry of Economic Affairs in 1993. Every year, eligible candidates are subjected to a rigorous and stringent selection system that covers four major aspects of “R&D”, “Design”, “Quality” and “Marketing” to identify outstanding products that offer “Innovative Value” while satisfying the key criterion of being “made in Taiwan”. Products that have been selected for the Taiwan Excellence Awards would serve as examples of the domestic industries and be promoted by the government in the international market in an effort to shape the creative image for Taiwanese businesses.

Let’s Meet 3 Leading Machinery Manufacturers from Taiwan!

Ching Hung Machinery & Electric Industrial Co., Ltd.

CHMER EDM The World’s Best Manufacturer Technology

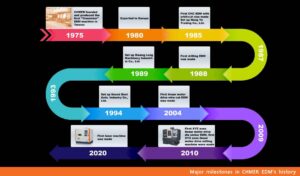

Founded in 1975, CHMER EDM (CHING HUNG) has fully dedicated to the technology and the quality of the EDM industry both in Taiwan and worldwide. The market sharing of CHMER is rated as the “First in Taiwan, Second in China and Fifth in the world”.

CHMER EDM’s headquater in Taichung, Taiwan

Mr. Brad Wang, General Manager of CHMER EDM, said “CHMER is the No.1 company in Taiwan for EDM, WEDM, EDM Drill, high speed milling, and laser cutting machines. It is also the first Taiwanese EDM manufacturer to be certified under ISO 9000 and CE and to win over many major Awards including Taiwan Excellence and Taiwan SMEs Innovation Award. Moreover, in the past 47 years, CHMER has already distributed over 18,000 machines in 55 countries. The company owns 90 sales offices around the world, which include those in Europe, USA, Japan and, of course, Thailand.”

Mr. Brad Wang, General Manager of CHMER EDM

Intelligence of New CHMER EDM Machinery RV series

RV853L – The intelligent linear motor driven wire cut EDM is designed with the moving column structure, remote monitoring functions, new i8 controller, AWT and many automation devices. RV853L carries a total number of 32 patents in various industries such as aviation and aerospace, energy and large mold.

Features:

- Intelligent RV machines build the intelligent production line: The new intelligent controller is equipped with the machine diagnostic and machine utilization analysis functions to improve the users’ benefits and build the production line to be more intelligent.

- Having an interface easy to use, an LED display screen to show machining status: With 19-inch touch-sensitive control panel and the interface that provides interactive dialogue windows.

- Having remote monitoring system and real-time control for machining information: Users can use their laptops to monitor real-time situation much more efficient.

- Automatic wire threading system of AWT for unmanned operations both days and nights [patent]: Our AWT completes the wire threading in 6 seconds with almost 100% successful rate.

- One Touch automatic sliding door, intelligent waterlevel control system [patent]: This system senses the water level to fill in and drain out and achieve the improvement of workpiece cooling and deslagging.

- High performance linear motor drive [patent]: The in-house high performance linear motor features high response with no vibration, no cogs, and no requirements for maintenance.

- i8 electronic control system is a new innovation with high-speed, energy-saving and stability: The new discharging circuit of i8 speeds can increase the speed up to 20% on high thickness workpieces of 150 millimeters and more. The use of FPGA is yielded with quick response, elimination of problems on wire breaking and IVC stable power supply which is best precise in repeatedly doing.

- The machine comes with the inverter chiller that optimally helps save energy: The internal temperature is controlled within ± 0.3°C and that the machining stability can be increased.

- Clean water circulation system to extend the service life of consumables [patent]: The filter life is doubled up compared with the previous system.

CHMER’s Machinery Technology Development to Enter into the Manufacturing World in Digital Age

CHMER would like to offer RV series with i-Connected System including Monitoring System app, Data Visualization app, and Intelligent Information Management Center.

Monitoring System app comes with mobile management function. You can use mobile phones or tablet PCs to monitor real-time machining and check information like machine status, utilization rate, and consumables life.

Data Visualization app is available for Android 8 and above, iOS 10 and above. It can show you the real-time machine information and receive push message and process the streaming platform. The main function is for data transmission and push:

- Receiving data in the machine from the machine database for transmitting through Web Socket.

- Real time information will be pushed by Firebase (Android) or iOS Developer.

Intelligent Information Management Center: The Kanban data can show the machine information in the factory and store the machine history for channeling onto the server.

Be Confident in CHMER’s Distributors in Thailand

CHMER has cooperated with N-TECH MACHINERY CO., LTD.in the Thai markets, by providing suitable sales consultations and efficient local service cooperations.

N-TECH MACHINERY CO., LTD.

HOT LINE SALES : 086-3046341

399/36-37 MOO 13 KINGKAEW ROAD, T.RACHATEWA,

A.BLANGPLEE, SAMUTPRAKARN 10540 THAILAND

TEL. (662) 136-5333 (AUTO) FAX. (662) 136-5334

HOTLINE : SALES (086) 304-6341, (086) 304-6347,

SERVICE (086) 304-6351

E-MAIL : [email protected], [email protected],

[email protected], LINE : @thaintech FACEBOOK : NTECH CNC Machine Thailand

For additional details, please visit: www.chmer.com

Tongtai Machinery Co., Ltd.

Experiences of Intelligent Machinery BuilderS of TTGroup Recognized Worldwide

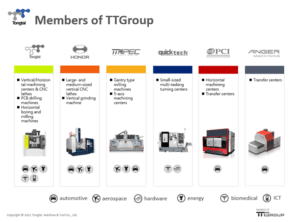

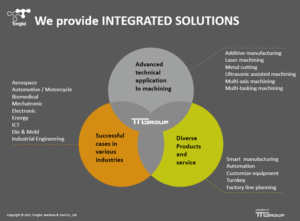

TTGroup is a global machine tools group consisting of 6 branded companies which are Taiwan based Tongtai, Honor, Quick-tech, APEC, France based PCI-SCEMM and Austria based ANGER MACHINING GmbH. TTGroup affiliates are business portfolios which has established to take care of customers’ requirements for equipment and solutions, technology applications and services.

Mr. Jamie Chung, Sales Manager, Tongtai Machinery Co., Ltd., Said “Members of TTGroup’s affiliates share technologies, resources, experiences and successful machining cases and build up horizontal integration through global networking. We share the same goals and expect to be a “Dream Maker and Future Leader” to create an ideal and profitable life for people.”

Mr. Jamie Chung, Sales Manager, Tongtai Machinery Co., Ltd.

Technologies which has been Regularly Upgraded…for Manufacturing Industry Progress

In terms of the product strategies, Tongtai provides various standard machines and customized, industrial-specific machines to meet the customers’ needs, and also provide customers with automation and turnkey solutions, and cooperate with the system dealers to integrate electromechanical equipment, software and production systems to achieve digital transformation.

The machine Having Been Developed on Technologies and Innovations and won Taiwan Excellence Award

TD-2000YBC- Winner of Taiwan Excellence Award 2017

TD-2000YBC multi-tasking turning center is an ideal machine for small and medium-sized workpiece machining. Its standard comes with the real Y axis, which ensures the machining precision to the customers. Other features include:

- Single power turret for turning and milling process is used.

- The 75 degree lathe structure allows for good chip removal and controllability.

- The machine gravity center is low, thus, making the overall structure rigid and strong.

- X/Y/Z-axis are orthogonal to each other, thus, allowing for high straightness and positioning accuracy.

A closer look at TD-2000YBC

Tongtai expects Thailand industry market to be optimistic in the long-term because of the complete supply chain and stable political situation. Tongtai Thailand was established more than 30 year ago and built its new office in 2017 to keep providing modern cutting solutions and upgrading services to support the customers continuously.

Tongtai will present its multi-tasking turning center: iTD-2000Y on METALEX 2022, a machine that can satisfy complex processes such as I.D. & O.D. Turning, Facing, Milling, Drilling and Y axis milling. It is equipped with Fanuc iPC and iCAP T to make programming easier and time-saving for changing new models.

Contact : Tongtai Machinery Co., Ltd.

36/30 Moo 7, Bangphli-King Kaeo Rd., Bangphli Yai, Bangphli, Samut Prakan 10540 โทร. 02-361-4708 แฟกซ์: 02-361-4711

For more information, please visit : www.tongtai.com.tw/en/ or http://www.tongtai.com.tw/th/

Chin Fong Machine Industrial Co.,Ltd.

Chin Fong and Its Progress in Metal Stamping Press Machines for Electric Vehicle Production

Chin Fong’s headquarter in Changhua, Taiwan

Chin Fong Group benefited from the liberalization of economic activities in the West and China in 2021, which eventually drove strong demands for stamping press facilities. Chin Fong’s 2021 revenue reached 5.482 billion Taiwanese dollars, which grew 26% compared to 2020. In 2022, the strong demand of new energy vehicles boosts the sales of related presses, sending the company’s first eight months revenue to 4.928 billion NTD, a 40% increase compared to the same period of last year.

Mr.Kuang-Hui Kuo, Manager of Chin Fong

Mr.Kuang-Hui Kuo, Manager, Chin Fong Machine Inudustrial Co., Ltd., Said “Chin Fong has been established for more than 74 years. Innovation is the concept we have always stuck to throughout the whole time. We have cooperated with excellent press makers from Japan, the USA, Germany, etc. Through the long-term exchange of know-how, we have accumulated enough technical experiences and converted them to self-owned technics. Furthermore, we have cooperated with the academic institutions for a long period and participated in every industry-academia cooperation, innovation award project, and systematic industry-academia R&D, which are all supported by the government.These efforts help our product innovation, business management, and engineering capability to be systematic.”

iForming PMS Technology Helps Production in Digital Age

Chin Fong rolled out a new model-ST1 series in 2021. The Taiwan Excellence awarded ST1-Straight Side Single Crank press series boast its solid frame structure via FEM design while reducing unnecessary design to balance structural rigidity and green product appeal.

ST1-110 – Winner of Taiwan Excellence Award 2022

It has perfectly combined the features of traditional presses and optimized structural design. The user-friendly touch screen panel not only improves the convenience of operation, but also displays the operating parameters for people to monitor the processing status in real-time. ST1 series can be widely used in stamping processes such as blanking, drawing, bending, marking, flattening, and trimming.

ST1 series can be integrated with iForming, which also won the Taiwan Excellence Awards. It can assist customers with smart management needs such as intelligent interconnection, real-time management, agile production, and data-driven decision making. In other words, it can help Chin Fong’s customers realize smart manufacturing and digital transformation.

Inside Chin Fong’s Factory, the smart wall and the assembly area of Intelligent Single Crank Power Press

iForming PMS is a self-developed and technology-driven solution system that utilizes the Internet-connected press to monitor the production process. The goal of iForming is to monitor real-time operations and use data analytics to improve manufacturing performance.

Sensors equipped on the press help collect information such as electricity and temperature. Users can review the information on Chin Fong’s APP connected to the press. This helps factory managers to sense early sign of machine issue, so as to arrange maintenance outside of the production peak. Besides showing the direct data collected onsite, iForming also prepares the statistical analysis directly, which could assist decision makers to improve their production schedule.

Chin Fong’s ambitions in Thailand

Thailand is an important automotive production hub in Southeast Asia and the Thai government is offering incentives to the electric vehicle industry to reduce carbon emissions and make the kingdom one of the world’s major production bases for EVs. There is an 80% cut in the annual road tax for privately owned, zero emission vehicles registered between October 2022 and September 2025. The government also said it would waiver any import tariffs that apply to the local production of battery powered passenger cars, minibuses and pickup trucks until the end of May 2025. The tax exemption applies to the vehicles produced in the country’s tax-free zones and free trade areas in industrial estates.

Chin Fong’s products have been widely used in making new energy vehicles (NEV), which is seen as one of the most booming industries in the upcoming years. Therefore, the company will stick to its strategy. It plans to keep expanding its business in Thailand through the service experiences they have accumulated in the NEV sector. Chin Fong will continue to integrate smart machinery and intelligent forming production management system to assist customers enhance competitiveness and increase profits.

For additional details, please visit: https://www.chinfong.com/en/index.php